Evaluating Scaling Risks – What Is The Big Picture?

Scale management, and the modeling and risk assessments that support it at the design stage of a project, is a critical part of the field development process for deepwater oil and gas developments. In many cases, scaling risk assessments are undertaken very early in the appraisal and concept selection process and with minimal supporting data; however, the implications of such studies can drive field design and affect the commercial viability of a project.

This GATEKEEPER provides an overview of the decisions which are the truly important outcomes from this process, and outlines the risks we incur by setting our scale management and associated field design philosophies early in the life of a project. It also addresses the ways in which we can improve the rigor and robustness of the scale assessment process. Finally, it emphasizes the need to maintain an understanding of why the work is being undertaken from a decision support perspective, so that it does not devolve into a program that focuses on modeling ever more scenarios without consideration of the end game.

OPTIONS FOR EVALUATING SCALING RISK

There are two primary tools available for determining the likely scaling risk for a new deepwater development. The first of these methods involves the use of software packages to model the proposed system and the interactions between the produced hydrocarbon(s), formation water(s) and injection water(s). This often includes evaluating the impacts on the production system scaling of measures such as subsea pumping or gas lift.

Although many models are available for undertaking scaling assessments, and many of these have been tried and tested against experience from multiple operating assets over many years, the main limitation of this approach is that its value may be limited by the quality of data available, most notably the quality or availability of water analyses for the field.

Other areas where software models can struggle are where initial reservoir pressures are outside the proven ranges of the model algorithms, as seen in a series of proposed deepwater developments where downhole pressures may rise to 25,000 psia (~1,725 bar), or where simpler models do not fully account for the interrelationships between waters and hydrocarbons when determining the combined fluid pH, hence carbonate scaling risks.

The second method that is used to evaluate scaling risk is to evaluate analog fields, and use this information as a baseline for similar planned developments. This can be an effective approach in cases where there is a mature deepwater play around the proposed development, such as for the Miocene trend in the Gulf of Mexico where formation water compositions and scaling risks look broadly similar across many fields in the Garden Banks, Green Canyon and Atwater Valley areas. This approach, however, provides much less value in areas where there is less prior development (e.g. the Lower Tertiary in the Gulf of Mexico) or where formation waters are subject to greater variation in local composition (such as West Africa).

FOUR CRITICAL QUESTIONS

In GATE’s experience, there are typically four critical questions that need to be addressed by any scaling risk assessment exercise:

Do We Believe the Water Analysis?

Where Do We Inject Scale Inhibitor?

Do We Need to Design for Scale Squeeze?

Do We Need Sulfate Removal?

DO WE BELIEVE THE WATER ANALYSIS?

Formation water samples are often unavailable for a particular field during concept selection and initial design, when many of the major scale management impacts need to be assessed. Alternatively, where waters are available they may be of dubious quality, be heavily contaminated with drilling and completion fluids, have been subjected to limited analysis, or have been gathered from non-producing zones that may be irrelevant to the target pay.

This is an area where scale modeling comes into its own. Not only does it highlight inconsistent water analyses, but it enables the target water analyses to be evaluated as a range of values to ensure that the design basis for a field is not predicated on a single water analysis or an unreasonable and overly conservative value. This is highlighted in Figure 1, where an over-saturated original analysis is evaluated on a risk map to identify a range of potential barium and sulfate concentrations.

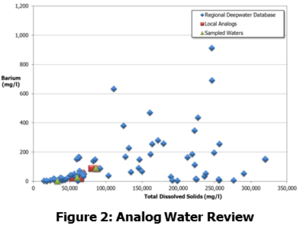

The use of analog data, where it is available, can be used to validate modeling results and support the determination of whether or not a water sample is truly representative of a particular field. This approach works most effectively when data is available from a large number of projects. The example in Figure 2 shows the comparison of three new water analyses with fields that are considered to be local analogs, as well as a broader range of values from the larger region.

WHERE DO WE INJECT SCALE INHIBITOR?

Once the expected formation water compositions have been narrowed to a reasonable range based on available water analyses, knowledge of the actual reservoir characteristics and the findings from analog developments, the major field development uncertainties can begin to be addressed.

The first question that is often faced is where does scale inhibitor need to be applied?

For many projects this can be answered relatively simply. If the issue is sulfate scaling due to water injection, then placing the injection point as low in the well as practicable is usually necessary. If the primary threat is carbonate scaling, then placing the injection point upstream of the bubble point is sufficient for many systems. A point of caution that is worth noting is that the rule of thumb regarding bubble point and carbonate scaling does not always apply. For deep, high-pressure reservoirs, the magnitude of pH change in the produced fluids may occasionally be sufficient to drive carbonate scaling above the bubble point.

DO WE NEED TO DESIGN FOR SCALE SQUEEZE?

Scale squeezes of deepwater wells represent a high cost, and potentially high consequence activity that can fundamentally alter the selected field development option for a field. The need for squeezes is most simply characterized by asking whether scaling is likely to occur in the producer completions or near wellbore region. If the answer is “yes,” as for the case shown in Figure 3, then it is likely that the required scale management strategy will involve squeezes.

The frequency of squeezes often forms a substantial unknown that can have a profound impact on the economics of deepwater projects. In some cases, such as for several West African developments, this has been sufficient to drive a transition from subsea to dry-tree developments and the use of tension leg platforms exporting to an FPSO, rather than a subsea-to-FPSO option. Such considerations have also resulted in the addition of flowlines or service lines to large Gulf of Mexico developments to facilitate the monitoring of squeezed wells.

DO WE NEED SULFATE REMOVAL?

Sulfate removal provides a means to reduce or eliminate the need for scale squeezes in fields where sulfate scaling following the breakthrough of injected seawater at the producers presents a serious problem.

By reducing scaling risk over the base case seawater injection option, sulfate removal can prove to be a cost effective option for many field development scenarios, as evidenced by the costs presented in Figure 4 for a generic subsea field. However, this typically comes at the expense of an increased topsides footprint, with a requirement for additional water injection system complexity, and an overall decrease in injection system availability.

CONCLUSIONS

The historic approach followed by many projects has been to select a single water composition for inclusion in the design basis during the concept selection phase, and to then to run a multitude of models based on this base case and some relatively arbitrary, but increasingly conservative, sensitivity cases. This single water composition is often based on faulty data or assumptions due to the difficulty and uncertainty associated with gathering and analyzing downhole water samples.

Such an approach does not adequately capture the realities of a complex subsurface environment, and so increases the risk that the facilities will be substantially over or under-designed from a scale management perspective. This results in financial penalties, either in terms of unnecessary upfront capital expenditure or an inability to deliver maximum recovery from the target reservoir due to production impairments.

By focusing on the four main questions that inform the field design process, rather than modeling for the sake of modeling, it becomes possible to identify threshold conditions where step changes in water composition and scaling behavior drive critical project development decisions.

This systems-wide focus on the field development process provides clear added value in terms of supporting the development of a fit-for-purpose field design that does not rely on a narrow window of applicable cases, and that clearly identifies the degree of risk inherent with any selected design alternative.

REFERENCES

Jordan, L.C., Evaluating Scaling Risks: What is the Big Picture? SPE Production Chemistry and Chemical Systems Workshop, Society of Petroleum Engineers, New Orleans, Louisiana, March 2015.

Jordan, L.C.; Simsek, A.; Bracey, J.T.; Bargas, C.L.; Erdal, F.M., Dealing With Uncertainty – Impact of Scaling Prediction on Concept Selection for Deepwater Production Systems. NACE Corrosion 2011, Houston, Texas, March 2011.