Reservoir Souring Prediction

INTRODUCTION

There are many production reservoirs that produce high levels of hydrogen sulfide (H2S). Some of these fields know before initial production that there will be high levels of H2S and thus are able to design and manage accordingly; however, some fields will begin producing an increasing amount of H2S following water injection. These fields are more difficult to manage and require a means of prediction to help make cost-effective project decisions. At GATE Energy, we have the technical knowledge and experience to apply our own approach to souring prediction which can enable design and operational decisions to be made to mitigate the risks associated with such H2S production.

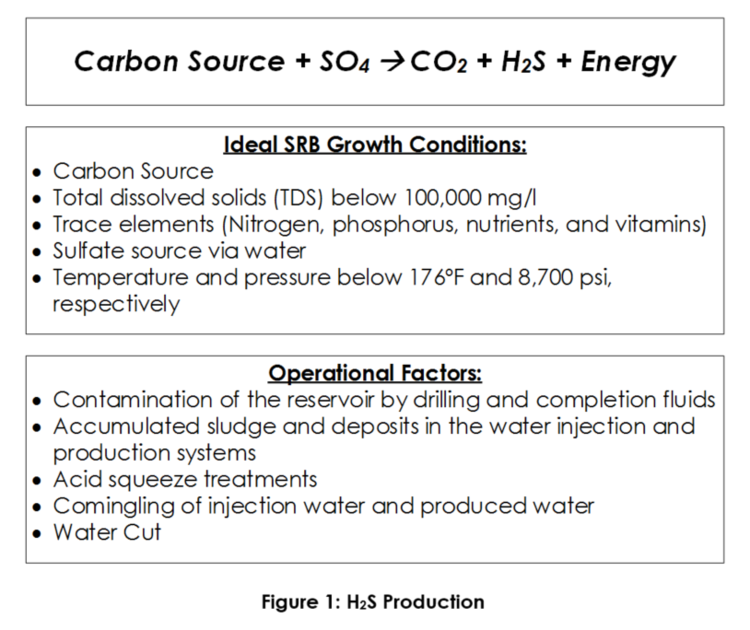

An increase in production of H2S in the reservoir fluids is characterized as reservoir souring. The primary source of souring is sulfate-reducing bacteria (SRB) following water injection into the reservoir as the injected water introduces either new reactants or new bacteria into the reservoir. SRB produce H2S as part of their metabolism. Operational factors that affect souring as shown in Figure 1.

This increased production in H2S creates additional health, integrity, and cost concerns in upstream facilities. Health concerns related to exposure to H2S are well-documented in the industry. As shown in Figure 2, the presence of H2S can lead to sulfide stress cracking (SSC) of susceptible metals in a process that can be accelerated by the presence of iron sulfide deposits. Sour production fluids typically increase both capital expenditures (CAPEX) and operational expenditures (OPEX) because of the need to mitigate the associated risks.

Most notably, the use of NACE-qualified sour service materials and the use of chemicals to mitigate souring and to treat export gas can all increase cost to a project. These costs are amplified if these mitigation methods are retrofitted, rather than implemented into the original design.

In order to manage the concerns and amplified costs that H2S creates, it is important to know the souring potential of the reservoir. Typical options to determine the souring potential of a reservoir include assessing analog fields, computer modelling, laboratory testing, and risk assessment:

Assessment of analog fields is a good starting point in determining souring potential.

This typically proves difficult because it is difficult to find good analogs, some analogs are missing key factors, and there is an inability to guarantee analogs will have the same behavior in the field.

Computer models predict the souring potential by assuming a series of chemical reactions to determine a rate-limiting component and calculating mineral scavenging and partitioning behavior.

There are several computer models available in the industry, but none of them account for all the observed aspects of souring.

Laboratory testing can provide a “reality check” for modeled results.

The laboratory cannot represent the complexity of a real reservoir in terms of geology, fluid properties, and bacterial population.

Risk assessment uses as a number of simple stoichiometric assumptions to generate a series of “what-if” scenarios to consider a worst-case in the absence of operational factors.

It is a conservative approach that cannot effectively represent the complexity of a real reservoir or the time-dependent reactions that result in H2S generation.

All of these options alone have their flaws. In order to best predict reservoir souring, a combination of two or more of the souring prediction options is recommended.

SOURING PREDICTION – THE GATE ENERGY APPROACH

At GATE Energy, a combination of computer modelling, risk assessment and, where applicable, assessment of analog fields, is undertaken to ensure a reasonable prediction of likely souring behavior can be developed. This approach can be used early in project life or during asset operation. The approach (shown in Figure 3) gathers and evaluates available data (assess analog fields), models the souring potential by computer modelling, and evaluates the souring risk using model results (risk assessment).

1. Gathering and Evaluating Data (Assessing Analog Fields):

Data vital to souring prediction includes the water composition of the formation and predicted injection water(s) and the pretreatment applied to the injection water (for instance, waters treated by sulfate removal membranes show a decreased propensity for souring than waters with similar sulfate contents that have not been treated).

The water composition data for the formation and predicted injection water, if available, is analyzed and compared to analog fields to determine if water samples are considered accurate. While analyzing, the key species data from the water samples to assess are the composition information regarding sulfate, carbon or equivalent acetate, phosphorus, and nitrogen or equivalent nitrate.

2. Souring Modeling (Computer Modelling):

Souring prediction modelling is done using a combination of an in-house stoichiometric, statistical modeling for high-level assessments and an in-house 3D reservoir model. The stoichiometric, statistical model incorporates the possible reactions involving the sulfate conversion rate by SRB, the maxima, minima, and means of key species, and variations in water ratios between formation water and injection waters to determine limiting species. The detailed reservoir model is able to predict a given environment’s reservoir prediction outcome.

These two models can be used separately or in tandem to provide solutions to both souring prediction in early design and during operation. In early design, the stoichiometric, statistical model is recommended to be used solely to be able to integrate multiple design cases quickly and cost-effectively. The model will provide results that are as accurate as detailed models in early design life due to the limited information typically available at that stage of the project. During operation, it is recommended to use the combination of the statistical model and the detailed reservoir model to be able to not only provide a look at multiple cases, but also be able to see a specified environment’s impact.

3. Evaluating Model Results (Risk Assessment):

Predicted model results can be evaluated to determine the risk to the potential facility. The in-house statistical model will provide results that show a distribution of H2S probability in the reservoir in a format that project teams are accustomed to working with and that will enable value project designs (e.g. materials selection, process design, souring control, injection locations, etc.) to be made more effectively.

Furthermore, the results from both the statistical model and the reservoir model provide H2S levels in the reservoir. These results can be combined with a partitioning model to evaluate the potential effects of H2S on the facility.

CONCLUSION

Reservoir souring is a costly and complex problem to mitigate once it has already occurred. Thus, predicting the souring potential of reservoir is critical. While every field is different, a souring prediction approach that takes into account computer modelling, assessing analog fields, and risk assessment allows for a cost-effective and stream-lined decision making processes. The resulting decision making ability improves the safety and integrity of the project and effectively reduces costs associated with otherwise unplanned mitigation requirements.