Integrated Fracturing & Stimulation

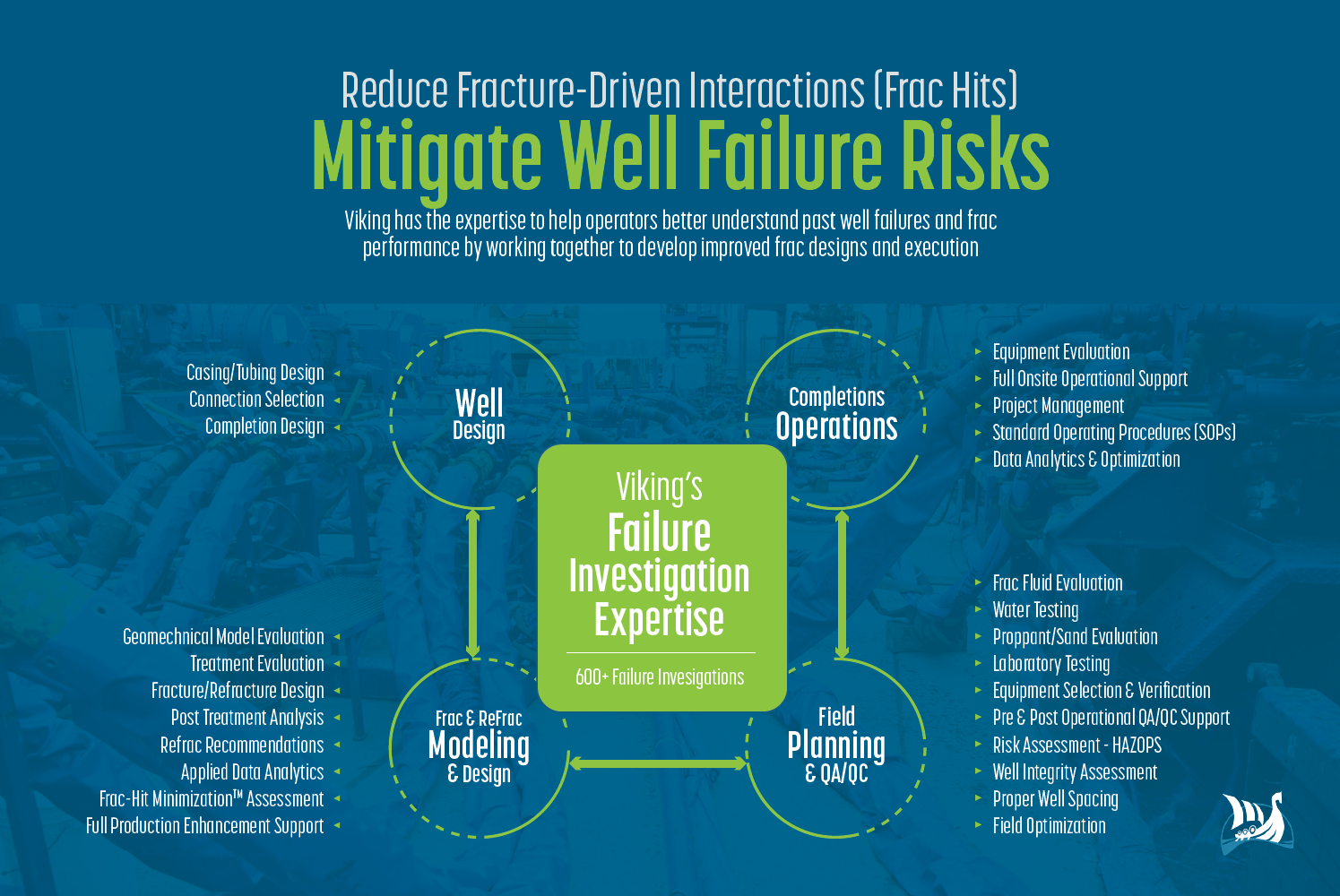

Viking has the expertise to help operators better understand past well failures and frac performance by working together to develop improved frac designs and execution.

We’ve developed a comprehensive program that relies on our failure investigation expertise (with over 600 failure investigations conducted) to reduce fracture-driven interactions or frac hits.

Our Services

Viking’s Frac-Hit Minimization™ Process

Frac & Re-Frac Modeling Design

Frac Field Planning

Completions Operations

Optimized Frac Design Using Viking’s Frac-Hit Minimization Process (FHM)™

The Challenge

Operators are facing tremendous challenges with being able to optimize their frac designs while minimizing risks of:

Fracture driven interactions or FDI (also known as “frac-hits”)

Well integrity failures

Production impairment/effects

High CAPEX from fraccing operations

Read more about our Integrated Fracturing & Stimulation Services below:

Solution: Viking’s Frac-Hit Minimization™ Process

Viking Engineering has developed the “Frac-Hit Minimization Process™” or “FHM™” to address these critical concerns in the industry for unconventional plays. The FHM Process is a holistic workflow that incorporates all areas and proprietary knowledge-base as mentioned below into one complete and seamless process.

The goal is to ensure a fit-for-purpose well design, for the completion/fraccing and production requirements of the well based on the reservoir at hand

The FHM™ Process – Foundation

The FHM™ foundation is based on Viking’s proprietary knowledge-base:

Frac-Hit or FDI Risk Quantification

This unique process is able to quantify potential risks to operators pertaining to FDIs and helps optimize completion/frac designs to maximize production while minimizing frac stages.

The evaluation consists of analyzing all pertinent variables including geologic factors such as faults, frac orientations, stress ratios, well spacing, well trajectories, and other. The evaluation also consists of analyzing well designs and applicability to reservoir requirements from a fraccing and production perspective. A risk component to well design and well integrity also plays a key role in the process.

Well Failure Database

Viking’s FHM™ process is able to provide potential well integrity failure risks and probabilities by utilizing a proprietary well failures database developed over the years. This database consists over 500 failures from a variety of different operators.

Viking’s vast experience with failure investigations provide critical lessons learned that are then incorporated into our FDI Risk Assessment and the well and completion designs.

Frac-Hit or FDI Risk Quantification

This unique process is able to quantify potential risks to operators pertaining to FDIs and helps optimize completion/frac designs to maximize production while minimizing frac stages.

The evaluation consists of analyzing all pertinent variables including geologic factors such as faults, frac orientations, stress ratios, well spacing, well trajectories, and other. The evaluation also consists of analyzing well designs and applicability to reservoir requirements from a fraccing and production perspective. A risk component to well design and well integrity also plays a key role in the process.

Frac & Re-Frac Modeling & Design

Viking Engineering provides operators with a holistic and multidisciplinary approach to hydraulic fracturing and stimulation-related operations. From fracture design to execution and post-treatment analysis, Viking’s approach offers the operator technically supported decisions when conducting fracturing and stimulation operations.

Before any modeling can be conducted, it is imperative to establish the most robust geomechanical model possible, including accurate and realistic formation and rock properties. This allows simulation results to represent precise in-situ conditions. Viking aims for optimized production results that last. This is achieved through accurate fracturing modeling and design which allow operators to make the best decisions at the time of fracturing the reservoir.

Viking uses industry-recognized hydraulic fracturing software for all modeling, design, and evaluation needs. We also provide full engineering support with experienced personnel onsite and around the clock.

Our Frac & Re-Frac Modeling & Design Services

Geomechanical Model Evaluation

Treatment Evaluation

Fracture/Re-Fracture Design

Post Treatment Analysis

Refrac Recommendations

Applied Data Analytics

Frac-Hit Minimization Assessment

Full Production Enhancement Support

Frac Field Planning & QA/QC

The backbone for any successful fracturing and stimulation operation is the QA/QC program behind it. In order to achieve all frac program objectives, every single part of the operation needs to be up to spec. Robust operating procedures also need to be in place to achieve design requirements.

Viking Engineering provides the operator with a comprehensive QA/QC plan tailored to each project to assure the success of the fracturing and/or stimulation operation. Viking’s team possesses a broad experience in all aspects of the QA/QC implementation program from material selection - including frac fluid, water, proppant/sand, chemicals - all the way to pumping and monitoring equipment.

We fully believe that in order to complete a successful operation, the collected data needs to be accurate and precise to be able to properly evaluate and further optimize the next job. For this reason, as part of this program, Viking provides full support on the required data acquisition plan and data analytics.

Our Frac Field Planning & QA/QC Services

Frac Fluid Evaluation

Water Testing

Proppant/Sand Evaluation

Laboratory Testing

Equipment Selection & Verification

Pre & Post Operational QA/QC Support

Risk Assessment - HAZOPs

Well Integrity Assessment

Proper Well Spacing

Field Optimization

Completion Operations

Viking Engineering provides onsite support for all fracturing and stimulation operations. The onsite Viking team ensures that operations are executed as it was designed and planned while making sure to achieve the project objectives. This gives our clients peace of mind throughout the process.

As part of this integral service, Viking’s team provides support for fracturing and stimulation equipment selection and verification. We also ensure that all equipment is tested prior to mobilization to location, to assure its compliance with the project and job requirements. From pump units, blending equipment, chemical dosing systems, high-pressure lines, and accessories, all the way to monitoring and measuring devices, Viking will confirm that equipment is tested and fully functional prior arriving to the job location. This simple practice avoids unnecessary delays that might affect job execution and project economics.

In addition, Viking’s experts help operators review and adjust all fracturing and stimulation standard operating procedures (SOPs) to ensure they meet project requirements.

Our Completion Operations Services

Equipment Evaluation

Full Onsite Operational Support

Project Management

Standard Operating Procedures (SOPs)

Data Analytics & Optimization

Consult Our Specialist

Related Resources