Get Producing Quickly with Our Pipe Experts

As the field services arm of GATE Energy, BlueFin provides flushing, testing, cleaning and joint integrity for energy facilities and assets.

Hiring an Inexperienced Team Leads to Lost Time & Rework…

While a low bid may look good to the boss, hiring an inexperienced team can lead to expensive rework. Rework leads to waste. Waste of expensive equipment, waste of people’s time, and most of all, a waste of money. Some teams choose to cheapest route - whether that’s repairing it themselves or choosing the cheapest bid. But that doesn’t always work out for the best.

The consequences - lost production and an expensive bill.

Saving You Money in the Long Term

Experienced teams move faster and work hard to get you back up and running quickly. Extended uptime, more production and enhanced design life while avoiding safety and environmental incidents – that’s what we want.

We’re your Pipe Experts - we’re here for you, whether is flushing new piping or cleaning out an existing line. Our experienced crew is ready to get you producing quickly and make your life easier.

Your Energy Asset Can…

Have a Smooth Startup

Operate Cost Effectively, Reliably & Safely

Have Piping that Flows Reliably

Experienced & Responsive Field Service Teams

We understand that you have many choices when it comes to hiring field services’ teams, but if you are looking for an experienced team that’s responsive and communicative - call us! We have cross-trained staff, the equipment and the know-how so you’ll feel comfortable relying on our expertise.

Your Pipe Experts

Whether is a small umbilical tube or a large diameter pipeline, you can call us your pipe experts. Any size. Any diameter. We offer flushing, testing, cleaning and joint integrity services for energy and industrial facilities.

Updates Every Step of the Way

Our Field Services team is dedicated to building trust and long term relationships. That’s why we work proactively during the planning of our projects so that we can provide high quality execution. With our highly responsive teams, you’ll be kept updated every step of the way. We’ll always respond and always have your back.

Executed Right the First Time

We strive to be the best question askers in the room. That’s how we discover your highest priorities and determine the details in the beginning. If we plan beforehand and produce quality work, we mitigate project failure.

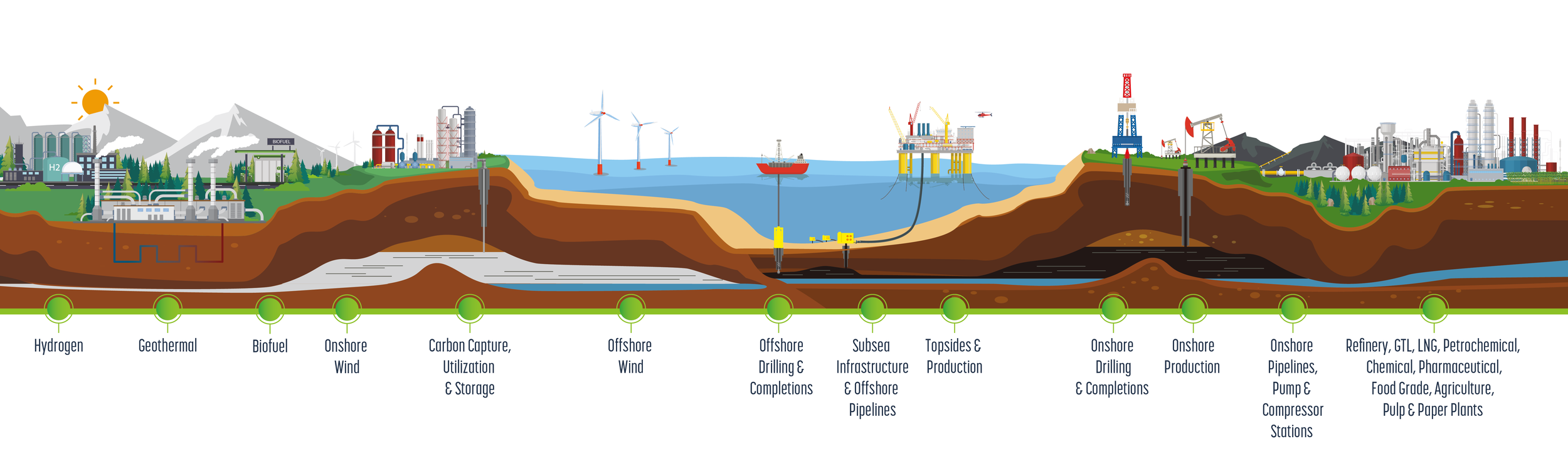

Markets We Serve

Product & Technology Highlights

Your Path to a Successful Project Starts Here…

We want to completely align with your interests. That’s why we develop our proposals, work processes, recommendations, etc. based on your specific project and needs. And it all starts with our initial meeting…

1. Let’s Meet

We'll meet to understand your highest priority challenge/problem and understand your desired outcome.

2. Identify Solutions & Plan

Our experts will work backwards from your desired outcome, through the systems and expertise needed to achieve it, and identify the most cost effective and efficient solution(s).

We will share our recipe of methodologies and processes that have been proven to help other clients and can help you. Together, we'll agree on the most optimum, tailor-made plan to solve your problem.

3. Execute & Communicate

We’ll execute your chosen plan with consistent and frequent project updates (including cost and schedule specifics) until completion. Communication is key at this stage.

4. Lessons Learned & Feedback

We’ll follow up with lessons learned and client feedback so we become even more efficient and effective as a company and as an industry.

What Our Clients Are Saying

- Enven Bolting 24”, Enven

“We have already scheduled to use the team again based on the performance of this work.”

- Buffalo Bayou HDD Pre-Test, Pilgrim Construction

“There were a lot of challenges on this job and y’all did a great job with dealing with them. Everything was in good working order. I think blue Fin did a great job at competitive rates. I will definitely use the company again.”

– Orion ACC Test, Performance Contractors.

I’m more impressed with their ability to adapt efficiently in the field as conditions/procedures of a scope change.

– EW 1006 #3 Decommissioning, Penn Virginia.

[The] equipment looked in good condition and performed well. Services and fees in alignment with quote. Good discussion and active participation in planning phase. Detailed procedures and understanding of the work scope. Good front end planning and participation. Crew leads had very good understanding of the work scope and procedures and could adapt to changes using MOC process. BlueFin provides specialized services and I was satisfied with the performance and safety on this project.

– EW 1006 #3 Decommissioning, Oceaneering

— EI 252 Flush & Idle, Crimson Gulf

— Hydrotest, Genesis Energy

“The team met all challenges the project gave and continued to provide solutions through project completion. BlueFin is definitely a company to consider for future projects and recommend to others.”

— BlueFin PPIS – Empire Auger 12 Pipeline Flush

“Jason, Ducky, and Gilles were great assets to deal with the issues that arose and managing the expectations of a platform owner that is most likely the toughest to work within the Gulf of Mexico. Performance was great and everyone worked through the multiple curve balls that we encountered. Equipment was placed on standby and in service in prudent a prudent manner to help control the costs.”

— BlueFin PPIS – Empire Auger 12 Pipeline Flush

— BlueFin PPIS – Shell Auger Accumulator Flush

BlueFin responded promptly and eagerly in finding the correct solutions whether that was related to unexpected additional and interim mobilizations, or sourcing equipment or parts.

Overall, the performance from BlueFin was exceptional from engineering and management through offshore execution.

- Katmai Pre-Commissioning, Subsea 7

“The small crew of guys we had on site were professional and knowledgeable in all aspects throughout the project.”

— Excel Contractors

- Katmai Pre-Commissioning, Subsea 7

“The quality and cleanliness of the provided and used equipment was exemplary. Your project manager was very helpful in scheduling and providing a crew to respond. I would recommend your company repeatedly in the future.”

— Tucker Midstream Services

— Fab Hydro Alabama

“The test that was performed was exceptionally executed by Saul and Luke. They were excellent representatives of your company. Both were exemplary in their demeanor and in their knowledge of the services that they provide.”

— Fab Hydro Alabama

“This project was monitored by our senior management and was highly visible within the company.”

— Spread 2 Construction Team

The technical expertise, skill, and experience provided by BlueFin as well as the strong commercially competitive bid during tender and flexibility to commercially work with Subsea 7 even after project award demonstrates BlueFin's commitment and effort to work with Subsea 7.

- Katmai Pre-Commissioning, Subsea 7

Responsive Pipe Experts That Make It Work Right The First Time

Hiring an inexperienced team can have disastrous consequences and turn those cost savings you thought you had into an even more expensive bill. Don’t get caught in the trap.

Our teams are not only specialists, but are also cross-trained in different field service disciplines. We promote and utilize the best practices and processes so our people and your people return home unharmed, with no negative impact on the environment and resources.

We support the pre-commissioning, maintenance, remediation and decommissioning of energy facilities and assets focusing on flushing, testing, cleaning and joint integrity of piping systems and pipelines.

We believe we can make projects work right the first time by staying disciplined with proper planning, quality work, and straight-talking communication.

We owe it to the world to deliver energy efficiently. Wasting people’s time, money and the earth's resources is not sustainable.

Energy is a tangible resource demanding ingenuity, application, risk taking, and grit. Reduce your risk and call our responsive, experienced pipe experts.

Project Experience & Case Studies

A large liquefied natural gas (LNG) producer, with multiple plants along the Gulf Coast, required standard leak testing services during the commissioning and startup phase for their newest plant.

An Independent E&P Company operator’s main 6” infield flowlines on the Gulf of Mexico shelf had been experiencing problematic organic deposition, ultimately rendering it inoperable. The production was re-routed through a parallel 4” line that allowed for production to sustain while the paraffin-stricken line was temporarily abandoned.

A mid-size upstream operator experienced progressively lower flow rates as the result of solids restrictions. Routine pigging procedures were not applicable on the produced water system, as the HDPE product pipe configuration was considered to be unpiggable with conventional methods. This liability reduced the engineering startup flow rates drastically, which initially calculated a rate to move produced water equal to or faster than the production rate. Slower flow rates impeded production and ultimately had a negative reflection for the production asset.

A GoM upstream operator engineered a pre-existing 22” gas pipeline and a pre-existing 8” oil pipeline for common use. This re-engineered scope eliminated CAPEX costs on installing a new pipeline and decommissioning costs on removing the in-service assets by utilizing in-place assets to achieve the new production requirements.

A midstream operator sought flow assurance and integrity services for a gas pipeline with blockage concerns. The unknown location and makeup of the pipeline restriction prevented the operator from performing routine pigging operations. In order to remain compliant with current regulatory standards, a sound remediation method that targeted the blockage area was required in order to successfully plan and execute a hydrostatic pressure test.

An operator of a Liquified Natural Gas (LNG) offshore loading facility required mechanical torque value verification on multiple structural assemblies in order to abide by the manufacturer’s recommended specifications and standards.

An operator of an onshore Liquefied Natural Gas (LNG) micro fuel facility sought integrated solutions from a single source contractor. Ongoing activities with multiple construction groups were working compressed schedules in order to ready the facility for a re-purposed product. Direct technical commissioning support became an value target during the early phase of project execution, as pressure testing and torque value verification for 600+ connection joints demanded specific expertise.

A Gulf of Mexico operator required a safe method to dewater a subsea pipeline upon a recent integrity test. Previous attempts to dewater the pipeline of the hydrotest medium with a foam pig proved unsuccessful. Importantly, the said pipeline was documented to contain heavy paraffin accumulation. Furthermore, the pipeline asset required an application that could mitigate the multi-diameter profile while assuring the client of a complete dewatering task. BlueFin’s casted SoliGel pig was designed to travel throughout the different pipeline diameters while mitigating flow assurance challenges and using production gas as the propelling medium.

A midstream contractor required competent, turnkey commissioning solutions in order to meet an established start-up date. The project consisted of 225 miles of 24 inch NGL pipeline in West Texas. Knowledge of pipeline integrity parameters, SIMOPS scheduling, logistical resources, and proven field personnel were critical to project award approval.

A Gulf of Mexico operator planned a well re-completion of a new reservoir and planned to use an existing flowline. Historical data determined significant paraffin deposition across the flowline. Due to well reservoir modeling analysis, the preexisting flowline warranted an aggressive but confident cleaning program to ensure that the volume capacity was realized.

A pipeline operator required a full line hydrostatic test of a 22-inch crude oil pipeline. The line would be tested in 4 segments. During initial line fill, the pig got hung up and bypassed nearly the entire line fill volume. Once the decision to move forward was made, BlueFin sourced equipment and refilled the line with an alternative water source within 3 days. One segment failed initial test. After repairs, all four segments were successfully tested using electronic data to justify pressure changes.

Startup engineering requirements specified that produced water flow rates should be equal to or faster than the production flowrate. Lesser flowrates would impede production and ultimately create problems in the production schedule and budget. After a considerable production timeline, the operator began to experience severe flow assurance issues on the produced water pipeline as the result of solids buildup.

A major midstream gas transmission company required stress corrosion cracking (SCC) integrity assessment services by hydrotesting to remain compliant with regulatory specifications. The project consisted of a single 101.9 mile pipeline with both 24 inch and 26 inch diameter pipe. Significant environmental hazards were encountered from pipeline contaminants. Additionally, unknown to the pipeline operator, the pipeline contained a significant amount of debris.

A GoM operator of a 6-inch subsea oil production flowline experienced severe paraffin blockage. The said deposition prevented a successful hydrocarbon de-inventory procedure in order to properly abandon the asset per compliance regulations. Due to insufficient pump rates, the operator faced expensive, complex subsea intervention tasks based upon routine flow assurance methods typically applied in decommissioning scopes of work.

An operator of a mini-TLP experienced flow assurance problems in a subsea oil production flowline system. Operator knowledge and production history identified the issue as a paraffin blockage. Unsure of the blockage location and remediation method, several failed attempts at pressure cycling from the subsea and platform sides resulted in a mechanical remediation need.

A GoM operator experienced problematic pressure differentials over a period of time, ultimately resulting in a completely plugged 6” flowline. Heavy paraffin solids completely plugged the flowline and prevented the transportation of liquid product. Upon an evaluation of available remediation methods, an extended reach mechanical solution was selected.

A major midstream operator required decommissioning solutions for an aged gas pipeline asset. In order to properly abandon the said infrastructure in compliance with BSEE and state regulatory departments, engineering managers determined that an inert gas medium would mitigate several risks. As important, the asset contained a large amount of residual liquid product that required safe capture and disposal.

A midstream company required a Department of Transportation (DOT) integrity assessment on a 30-inch transmission gas pipeline. In order to meet federal compliance standards for continued gas operations, the operator elected to execute a hydrostatic pressure test between an existing compressor station and a mainline valve location.

A Gulf of Mexico upstream operator required pipeline abandonment solutions for one 6 inch pipeline. The operator’s permitted Department of Interior (DOI) decommissioning obligation required a seawater flush volume equal to 110% of the internal pipeline capacity.

A major midstream gas transmission company required Stress Corrosion Cracking (SCC) integrity assessment services to remain compliant with regulatory specifications. The pipeline was installed in the 1970s and was located in an environmentally sensitive area with high stakeholder interest and visibility. Further increasing project sensitivity, the pipeline owner expected multiple ruptures during the hydrostatic pressure tests phase. In order to compensate for this risk, an extensive outage period was scheduled and communicated to all customers.

A GoM upstream operator experienced problematic pressure differentials. Over a period of time this resulted in heavy paraffin deposition and ultimately caused several pigs to become stuck in the 6” flowline. Upon an evaluation of available remediation methods, an extended reach mechanical solution was selected to remove the lodged pigs and properly remediate the paraffin deposition.

A GoM operator witnessed a leaking 6” pipeline. Upon repairing the visual leak and attempting to perform a successful hydrostatic pressure test a second non-visual leak occurred, ultimately resulting in extended production loss.

In order to perform a second assessment and bring production back online, the pipeline assessment required a 100% fluidpacked volume of seawater to ensure an oxygen-free environment.

A major midstream gas company required a Stress Corrosion Cracking (SCC) integrity assessment in order to remain federally compliant. The project schedule was of critical importance due to the customer’s demand date for product transmission. This schedule demanded that BlueFin couple engineering subject matter experts and management resources to deliver a work plan that would meet the customer’s deadline.

SafeHeat® technology, custom thermal fluids, and flow assurance engineering provide total approach for plugged GoM pipeline.

Technical expertise and responsive management provide GoM operator with a successful offshore gas pipeline reinstatement.

Integrated mechanical and pipeline services provide bundled solutions for independent GoM operator.

Qualified personnel and responsive management provide gas storage company with multiple SIM OPS pipeline pre-commissioning scopes of work.

Split frame lathe technology delivers field machining solutions for one Supermajor in the Dragon Field block.

Brochures & Spec Sheets

BlueFin’s Pipeline, Process & Industrial Pocket Guide

Compact, Economical, Retrievable Production Packer

Single-Grip Mechanical Production Packer

Prevents Tubing Movement, For Rod Pumping Applications

Zonal Isolation, Tubing Retrieval & Temporary Zone Abandonment

Packer for Any Production Application

BlueFin’s Thru Tubing Control Systems

BlueFin’s Downhole Gauge Comparison

Expertise in controlled bolting allows measurement and monitoring vital for joint integrity

BlueFin’s Water Treatment & Filtration

BlueFin’s Inline Isolation Tool

BlueFin’s Cold Cutting & Field Machining

BlueFin’s Hydrostatic Pressure Testing

BlueFin’s Flow Assurance & Pipeline Cleaning

BlueFin’s Pipeline Deposit Mapping

BlueFin’s mechanical approach to solving deposit and blockage challenges

BlueFin’s Adaptable, Unstickable Pig

Patented, Controlled Cleaning & Recoverable Jet Pig

60 Barrel, Two-Compartment Fluids Handling Tank Used For Various Applications