Hassle-Free Energy Production on Cruise Control

As the specialty engineering arm of GATE Energy, Viking Engineering supports the design, optimization and integrity of energy facilities and assets.

Rework Leads to Waste – Waste of Money, Earth’s Resources & People’s Time…

You may have saved cost and time in the beginning by cutting out that expensive _______ , but little did you know, that expensive ________ would have led to longer facility uptimes, decreased operations cost (repairs), and decreased headaches for the boss.

Gaps in the design process can lead to unexpected failures during operations. Unexpected failures and rework leads to waste. Waste of expensive equipment, waste of people’s time during design and repair, and most of all, a waste of money.

The consequences - lost production and reliability of your asset.

Ready for Extended Uptime?

The earth does not have an unlimited number of resources. Our people don’t have unlimited time. And our projects don’t have unlimited budgets.

But, extended downtime and unexpected failures shouldn’t be the norm. Extended uptime, more production and enhanced design life – that’s what we want.

We make our clients look like rockstars. You’ll gain a reliable partner that’s always got your back. We give you the technical background to walk into any situation confidently.

Your Energy Asset Can…

Have a Smooth Startup

Operate Cost Effectively, Reliably & Safely

Have Pipelines and Wells that Flow Reliably

Have Equipment that Meets its Design Life

“Big Picture” Engineering & Laboratory

Unexpected challenges and failures can be stressful – especially when you need to get your facility back up and running quickly or need to get the design out the door. Call us when you’re in trouble - our engineers have your back.

We Reverse Engineer Your Desired Outcome

We’ve seen it work and we’ve seen it fail. We are not a commodity engineering group – we are a multidisciplinary, specialty engineering group that realizes your dream, views your “big picture” and designs the solution backwards – so you get what YOU want.

We Optimize Assets to Reach their Full Potential

Well dying? Lines blocked? We work fast to get you back up and running quickly, even if it’s a quick fix while we find a real solution. The goal: keep producing.

We help you make informed decisions so you can increase production.

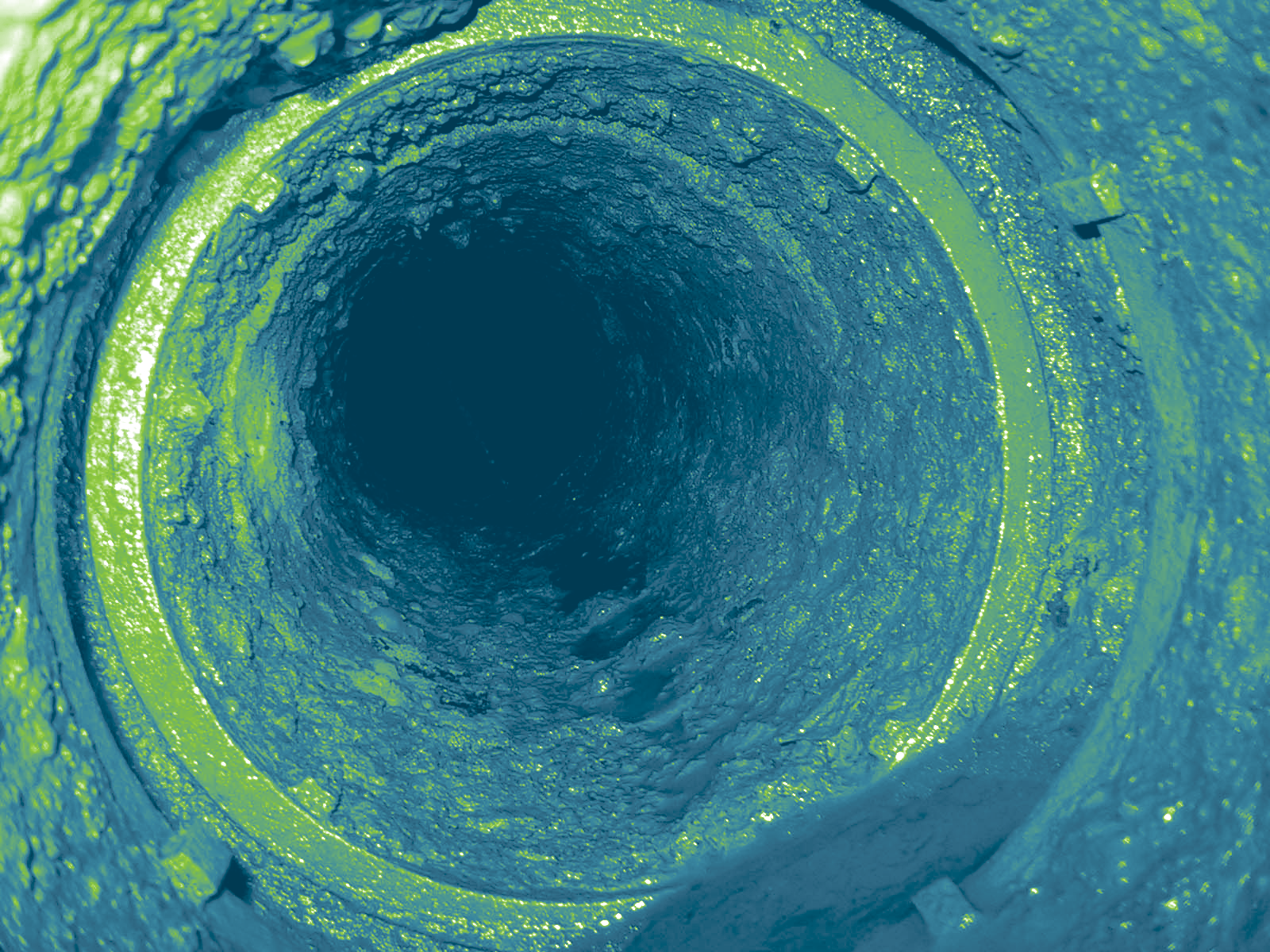

When Things Fail, We’ll Help You Find Out Why

Our metallurgical lab helps you find out what caused the failure and how to prevent the failure in the future. Our recommendations provide a path back to reliable and continuous safe operations.

We are straight-talkers, not sugar-coaters. We’ll give you the good and the bad.

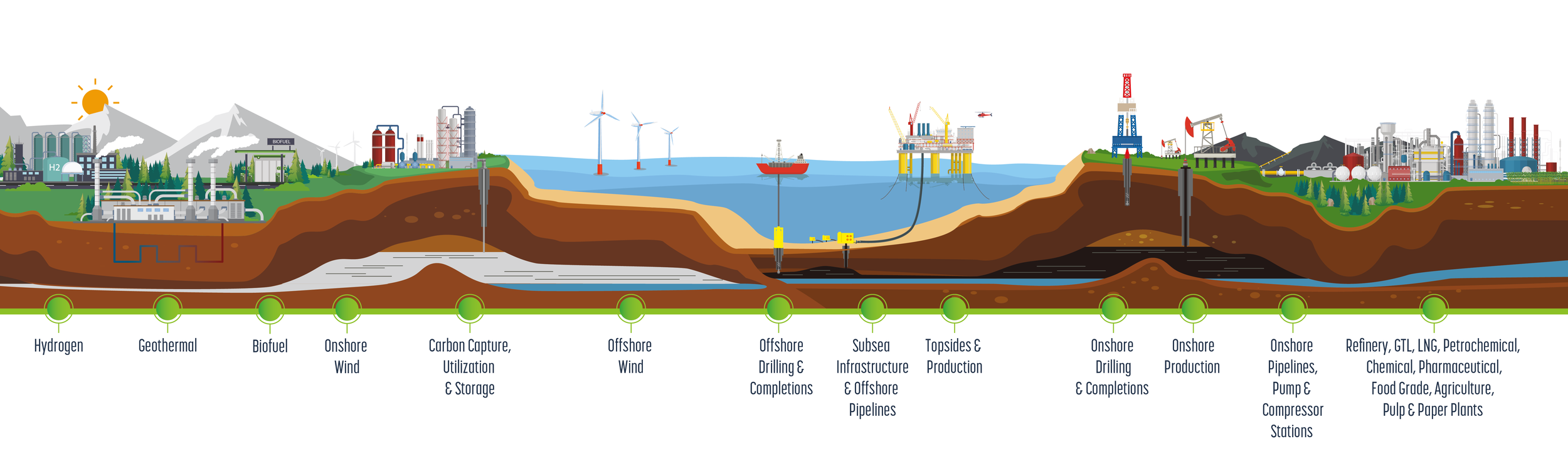

Markets We Serve

Our Engineering Services

Our mission is to provide you with comprehensive, cost effective planning and design for wells, pipelines, water injection systems, and chemical injection systems. Systems developed late in a project and in silos can’t reach the potential of becoming the powerful tools that they were developed to be. This is the industry culture change that Viking has set out to implement. We also offer flow assurance and operability, production optimization, and comprehensive blockage remediation services.

Our Metallurgical Lab Services

The Viking Laboratory provides fit-for-service evaluations, testing and analysis for evaluating complex downhole failures, pipeline failure investigations and forensic services for midstream and downstream clients and also provides services to the renewable energy sector. Our Expert Witness services will give you the facts, and only the facts.

Our lab is centrally located in Houston with easy Hot Shot access.

Your Path to a Successful Project Starts Here…

We want to completely align with your interests. That’s why we develop our proposals, work processes, recommendations, etc. based on your specific project and needs. And it all starts with our initial meeting…

1. Let’s Meet

We'll meet to understand your highest priority challenge/problem and understand your desired outcome.

2. Identify Solutions & Plan

Our experts will work backwards from your desired outcome, through the systems and expertise needed to achieve it, and identify the most cost effective and efficient solution(s).

We will share our recipe of methodologies and processes that have been proven to help other clients and can help you. Together, we'll agree on the most optimum, tailor-made plan to solve your problem.

3. Execute & Communicate

We’ll execute your chosen plan with consistent and frequent project updates (including cost and schedule specifics) until completion. Communication is key at this stage.

4. Lessons Learned & Feedback

We’ll follow up with lessons learned and client feedback so we become even more efficient and effective as a company and as an industry.

What Our Clients Are Saying

“We were very impressed by the content of the RBI report...We were very pleased with the quality of work that we have received on this project. GATE has done a great job of updating us on progress also.”

– Anadarko

“We have already requested further support on both the operations and engineering sides. We will continue to reach out to GATE for their guidance in GOM oil and gas processing design. Great job guys. Look forward to working with you in the future.”

— Stones FPSO

“I was very satisfied working with Sampath on the project. He is technically excellent, always responsive to calls and E-mails and was very pleasant and easy to deal with personally. Each phase of the project was always completed within the estimated time frame and the overall project was completed under budget. I could not have asked for anything more.”

- Shell

“Overall, very pleased with project and deliverables. Viking was ALWAYS very responsive to comment and suggestions. Major credit to Jorge for being able to convey Viking results in confident manner.”

— Noble Energy

“I feel very good with the model and information provided. I will have to wait until the system is utilized to see how close the pressures are to know how accurate it was. Always responsive and timely in delivery.”

- Tanos Field Optimization

“Working with Randy (Dinata) and Mark (Stair) always goes smoothly. I appreciate their consistency and in-depth knowledge on the matter should questions arise. Their responsiveness and clear communication really simplifies a potentially complex scenario. Extremely quick turnaround considering data quantity, and attention to detail.”

— Kosmos Bar #1 and SSC #1 Test Support. Kosmos Energy

“We look forward to working more with Lee as we move closer to project execution.”

- Talos

“Shelly Gallender and Peter Leaf were great. Quickly responded to emails and phone calls from me and the rest of the team. Always made sure someone was in meetings.”

- Shell

“Sampath Bukkuraju has been of great help by providing prompt and high-quality FA support to the Murphy Delta House team during the operational problems experienced during recent months with the Gas Export Pipeline. He is very thorough in his analysis, has excellent modelling and communication skills and is fast to respond to the requests/questions. I'm a relatively new to the Murphy team and he's been very easy to work with. I hope we can continue working together in the future for this project or any other scopes.”

- Murphy

— Engineering, Tullow

“Yougui (Zheng) has provided excellent support to the offshore paint technology program. He lead the yard trial of fast cure tank linings with detailed planning and successful execution. The work has paved the pathway for further technical evaluation and field deployment. Yougui also lead the technical evaluation of surface tolerant coatings and humidity tolerant coatings. Both technologies were approved for offshore application and they are in the process of offshore deployment. Yougui is intelligent and dedicated to the work, he has been a key player in the project.”

- Coating Support, Shell

“I can only compliment GATE on their reactiveness and commitment to support Tullow in resolution of the hydrate issue. There is nothing I believe could be done differently or better. The performance of GATE on their support with our hydrate remediate is a true credit to how the team has managed. The quality of response was excellent; specially the presentation of information/graphical plots was far superior to other FA companies Tullow has used. The proactive nature of the GATE team was exceptional. Prepared to support over festive period and weekends to resolve issues and provide feedback/information to allow TGL to progress to a solution.

— Tullow Oil

“Juan provided excellent information and project support throughout the planning and execution of this hydrate project. We were able to keep engineering/flow assurance costs relatively love, because there were not multiple engineers working on this project. Success!”

— W&T Offshore

“Ani, Eric, and Hugh, along with any others who worked on the project, did a very good job. They were diligent and stood firm in their values. We are pleased with the final project. This project was unique, the purpose was a little unusual and for us, it was the first of its kind. Therefore, it took a little work and discussion between GATE and us to get the final report completed, this is not unusual and not unexpected. GATE was responsive to our request and worked diligently to complete the project. We are grateful to the team for applying themselves the way that they did. GATE Team, thank you very much.”

— Petrobras USA

“Excellent turnaround time for queries whether technical or commercial. Even with the difference in time zones and locations, we were always able to facilitate group discussions when necessary. As well as completing all base scope the GATE team provided proactive alerts and advice based on the data we were feeding them.”

— Tullow Oil

Providing Ideas & Answers to Tough Energy

It never goes right 100% of the time, as much as we wish it would. And when you are in the middle of real challenges, you don’t want to have to wait for an answer.

You need a sounding board. Someone that can generate ideas, solutions or get you back up and running quickly. When you need answers to tough challenges, you need specialty engineers.

That’s our passion - to provide you with ideas and answers to tough energy challenges.

At Viking, we promote a systems-level view of engineering problems. This takes personnel with a broad knowledge of production systems and the challenges involved in designing, constructing, commissioning and operating them. Each Viking Principal has over 30 years of hands-on and management experience. This experience covers all phases of petroleum engineering and many technological applications. Our clients include energy companies, independent operators, legal firms and manufacturing companies.

Taking a larger view of the interactions and intricacies of the system as a whole enables us to develop an optimized solution that crosses many different disciplines and boundaries and provide fit for purpose answers to real operating challenges.

We are a close-knit company. This enables us to respond quickly to the needs of our Clients and also allows us to transfer learning’s and skills rapidly through our project group. We, in-turn, invest in our employees to a greater level than many other businesses do. We provide high caliber individuals for discrete high responsibility positions. This requires people that are willing to learn new things, able to transfer existing skills and knowledge to new situations, and who are able to manage and coordinate their activities and the activities of others.

We believe projects should be designed with an operator’s perspective, commissioned safely and on time, started up smoothly and produce nameplate production – all on schedule and on budget. We believe that most unexpected failures and downtime can be prevented in the design phase which leads to higher uptimes.

Having the sounding board and a trusted partner that you can rely on is important to us. We are straight-talkers, not sugar coaters. We’ll give you the confidence to walk into any situation confidently. We are solution seekers and look to provide certainty so your energy projects can meet their design intent.

Project Successes

Complete Field Integrity Project including wells, gathering lines, and facilities. Corrosion and Chemical Optimization and Development of a Viking Proprietary Tool for integrity.

Unconventional Plays, Horizontal Wells, Failure Analysis Work, Quality Assurance Work, Rig Operations

Unconventional Plays, Horizontal Wells, Failure Analysis Work, Quality Assurance Work, Rig Operations

Unconventional Plays, Horizontal Wells, Failure Analysis Work, Quality Assurance Work, Rig Operations

Material Selection for acid gas injection wells in west Texas. Materials Selection included production tubing, production casing, packer, production liner, Xtree and wellhead equipment.

CRA materials selection for production Liner for packer-less well designs in West Texas CO2 floods

Materials Selection for new well completion to include casing, and tubing. Corrosion Models were developed for these type wells using state-of-art software and modeling techniques

GATE Energy was responsible for pre-commissioning, commissioning, regulatory testing and vendor management for all Topsides systems of the King’s Quay FPU, both in South Korea and the United States / Gulf of Mexico. Viking, the engineering arm of GATE Energy, was contracted to assist with the development of the topsides standard operating procedures (SOPs).

An independent oil operator experienced four back-to-back casing failures in his Oklahoma shale program. These current failures and setbacks were eating into his budget and eroding stakeholder faith in the ability to complete wells.

His initial comment was, “I’m not getting any sleep – I need some help. You’ve got to help me stop the leaks!”

A winter-peaking natural gas storage plant undergoes a production expansion which includes infill well drilling and a gas compression system expansion.

Led study for independent oil and gas operator regarding the injection of flue gases from Gulf coast power plants to a Deepwater development for the purposes of enhanced oil recovery (EOR). This considered pretreatment and processing requirements for flue gases from natural gas-fired boiler plants, natural gas combined cycle plants, coal-fired boiler plants and integrated gasification combined cycle plants. Key issues considered were the ability of the pretreatment system to remove oxygen and water.

GATE was responsible for developing the overall Aseng Water Injection System Basis of Design.

GATE was requested to determine the potential risks involved in waterflood for the Neptune and Shenzi fields as a means to determine whether waterflood was a viable option for enhanced oil recovery. Based on this, GATE developed a waterflood philosophy document that details the problems and possible mitigation procedures for BHP’s use in determining whether or not to waterflood.

GATE provided in-house production chemistry support for the Horn Mountain, Atlantis and Thunder Horse assets.

GATE undertook a chemical vendor qualification process on behalf of Noble to procure the best suited chemical and chemical support for both the Aseng and Alen assets based on their fluids, and system along with their specific operational needs.

GATE leverages each chemical vendors based on performance of chemical, lab, ability to meet supply demands and upsets, price, experience and key criteria important to contractor and operator.

GATE undertook a rigorous qualification process on behalf of the client to BHP to procure the best suited chemicals and chemical support for both the Neptune and Shenzi assets based on their fluids, and system along with their specific operational needs.

BP Pipeline oversees the operation of 9 total oil and gas export systems from more than 20 different platforms in the GoM. The pipeline systems transport almost half-million barrels of oil and hundreds of MMSCF of gas daily from the producing platforms to onshore processing facilities.

The FAMP has been developed for BP Pipeline assets to ensure proper working of the high volume systems by organizing and delegating between operators, facilities, laboratories and onshore offices. By facilitating the review of system performance and operation, this information provides the basis of a continuous improvement approach.

As part of the scope of work, GATE was commissioned to develop two comprehensive, user-friendly screening tools to guide subsea flowline materials selection decisions for wet gas and waterflood during concept selection and design using field specific data.

GATE undertook an investigation into recovered, decommissioned equipment to determine both the cause of failure and investigate integrity of components that may not have failed. This information has proven invaluable to operators who can base the performance of other equipment of a similar type and construction in a similar environment. This was significant as the recovered materials ranged from the mud-line, to sea surface and topsides.

GATE provides Shell with cathodic protection design support for all their subsea projects. This includes coating selection (anti-corrosion and flow assurance) and qualification, which also involves interfacing with the coating yard. An important aspect of this operation is carrying out comprehensive quality audits of anode foundries and coating plants around the world.

GATE determined the risks and mitigation of risk associated with wet parking and flooding of a gas export pipeline with unfiltered seawater. The key concerns are corrosion due to microbes, oxygen corrosion, and drying to prevent hydrate formation when the pipe goes into service.

GATE undertook erosion and corrosion modeling in the flowline to develop sand production allowance and an erosion corrosion risk assessment. From this, a maximum rate of gas production that will allow the asset to maintain it design life was determined. This enabled the operator to safely increase production by 25% to without additional risk to the asset thereby increasing the Net Present Value of the asset.

GATE was responsible for formulating a detailed flow assurance strategy for the successful operation of Juniper production system. The project involved extensive cross-functional interaction, detailed study of the lessons learnt from similar fields in the region (offshore Trinidad), simulating a wide variety of what-if scenarios (both steady state and transient) to draft the flow assurance strategy and operability logic for optimized production.

Fuel Your Mind with Viking Technical Articles

Prediction accuracy for extended-reach laterals and high-intensity completions is improved by applying a Gaussian Process Regression (GPR) model with a Matérn kernel that accounts for parameter space sampling bias. The method adjusts predictions based on local data density and provides uncertainty quantification, increasing reliability in underrepresented regions of the design space. Applied to wells from the Bakken Formation, the model outperforms traditional approaches and supports confident forecasting for non-standard development designs.

So your pipe burst, your pump shaft snapped, or your welded joint split, and you need to figure out why and how to fix it. The next steps you take can make the difference between finding answers and leaving the mystery unsolved until the next failure.

Systems Theoretic Process Analysis (STPA) is a systems approach to hazard analysis. It is based on the premise that accidents happen when we lose control. They are a control problem, not a failure problem.

The GATE approach to risk ranking makes risk assessment easier, more accurate and more repeatable by incorporating LOPA insights into the risk matrix approach.

HAZOP is the most commonly applied process hazard analysis (PHA) methodology in the processing industries. It is also the most flawed!

This article discusses high-level technical considerations when refitting an existing offshore infrastructure for CCUS applications.

Energy is changing. Because of the increasing threat of the consequences of a warming planet, new sources of energy are being developed that are expected to slow this planet-wide change. Some of these are well-known, such as nuclear, wind and solar, while others require more work, such as hydrogen, 3rd generation concentrated solar and fusion.

The overall aim of carbon capture and sequestration (CCS) is to store carbon dioxide (CO2) in geological formations in order to reduce the amount in the environment and lower the risk of catastrophic climate change. The rate of CO2 emission and the amount of it in the atmosphere has been increasing steadily since the beginning of the Industrial Revolution in the early part of the 19th century.

There are several developments in the area of electrolysis which seek to reduce the cost, increase the yield, or even change the source of transportable hydrogen.

This calculator calculates the triaxial stress (VME) at a given depth.

This calculates AP collapse resistance for a specific pipe.

This calculator calculates the change in length of pipe hanging in the hole due to tension, ballooning, buoyancy and thermal effects.

This calculates AP collapse resistance for a specific pipe.

The recent global over supply of crude oil and soft demand has resulted in oil companies shutting wells in to prevent destroying value and to protect their balance sheets. The time frame, until production startup becomes economic, is uncertain and therefore, it is imperative that appropriate actions are taken to maintain and manage the integrity of shut-in wells and associated delivery systems.

The time frame, until production startup becomes economic, is uncertain and therefore it is imperative that appropriate actions are taken to maintain and manage the integrity of the available Installed Production Capacity during shut-in.