Engineering Lab Services

The Viking Laboratory provides fit-for-service evaluations, testing and analysis for evaluating complex downhole failures, pipeline failure investigations and forensic services for midstream and downstream clients and also provides services to the renewable energy sector.

Our lab is centrally located in Houston with easy Hot Shot access.

Our Services

Metallurgical Laboratory Testing Services

Materials, Corrosion & Engineering Mechanics

Failure Analysis Lab Services

Field Inspections

Modeling & Technology Lab Services

The Viking Laboratory is a full-service metallurgical testing laboratory offering a wide range of engineering and testing services.

Viking engineers and subject matter experts have the capability of designing and constructing customized fit-for-purpose testing fixtures and apparatuses based on extensive modeling and industry experience.

Additionally, Viking Laboratory is proudly a failure investigation, integrity and material testing company accredited to ISO/IEC 17025:2017.

Metallurgical Laboratory Testing Services

Viking metallurgical testing services capabilities include:

Chemical Analysis

Mechanical Testing

Tensile Testing

Hardness Testing

Materials Chemical Analysis

Metallographic Evaluations

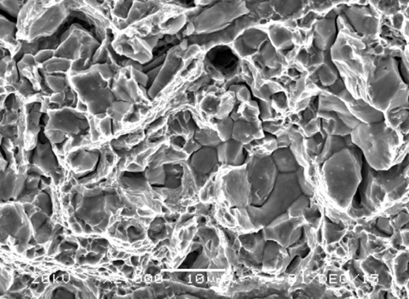

Fracture Surface Evaluations

Microstructural Characterization

Customized Testing

Materials, Corrosion & Engineering Mechanics Lab Service

Viking Engineers have extensive experience in supporting material selection for diverse industries, based on design, environment and application conditions. Our services include material recommendations review, material evaluations, sour service evaluation and testing, welding engineering, material compatibility assessment and material specification development.

We can perform corrosion studies in local settings (i.e., specific equipment), or wide field studies (i.e., oil and gas fields, facilities). We undertake our analysis with a holistic and integrated approach that includes multidisciplinary review of all factors contributing to the corrosion risk, from the operational and corrosive environment conditions to the material qualities.

Viking engineers are also capable of undertaking any type of Engineering Mechanics assessment by using commercial software packages (i.e., TDAS® , WELLCAT™ ,FEA Software ABAQUS ®, OLGA ®, OLI ®) or proprietary in-house developed models.

Viking engineers and metallurgists are also knowledgeable in the areas of:

Fit-for-service Evaluations

Microstructural Characterization

Materials Selection

Corrosion Testing

Fracture Surface Evaluation (SEM/EDS Fractography Evaluations)

Mechanical Testing (Tensile, Hardness, CVN)

Fracture Mechanics

Fracture Mechanics Testing (KIC, JIC, J-R)

Our Materials, Corrosion & Engineering Mechanics Services

Metallics and Non Metallics Materials Selection

Field Corrosion Studies

Fit-for Service Assessment

Integrity Assessments

Life Extension Engineering Assessments

Failure Analysis Lab Services

Viking Laboratory can help solve some of the most complex failures in the industry by offering a multi-disciplinary team of engineers. Collaboration with experts in other disciplines is required in certain circumstances to integrate the analysis of the evidence with a quantitative understanding of the different factors contributing to the observed material failure (i.e., state of stress, environment and background information on the design, manufacture, and service history of the failed component or system).

Viking Laboratory can also provide expertise from sample collection and courtroom expert witness, if necessary. In addition, we can help our clients avoid future problems by providing design modifications based on the failure causes.

Our services include conducting analyses on failed pipelines, downhole equipment, pressure vessels or any other critical structural component from any industry.

Our team of scientists and engineers can perform metallurgical evaluations, fracture surface evaluations, FEA, Root Cause Analysis (RCA) and a wide range of integrity assessments.

The Viking Team also leverages and applies lessons learned from the proprietary Viking Failure Investigation Database that contains findings from over 500 independent failures.

Our Failure Analysis Lab Services

Forensic Engineering

Field Investigation

Legal support / Expert Witness

Root Cause analysis

Sample Collection

Proprietary Failures Database

Fit-for Purpose Evaluations

Field Inspections

Viking engineers, metallurgists, and technicians, possess the knowledge, experience, and state of the art equipment to perform field inspections, such as:

In-situ metallography (replica testing)

Positive Material Identification (PMI) by Optical Emission Spectroscopy

Hardness testing

Non-Destructive Testing (NDT)

Visual examination

Magnetic Particle Inspection (MPI)

Liquid Dye Penetrant (LDP)

Ultrasonic Testing (UT)

Modeling & Technology Lab Services

Viking Laboratory leverage from the expertise of Viking Engineering subject mater experts in the areas of:

Finite Element Analysis (FEA)

Fracture Mechanics

Fatigue Analysis

Thermal-Hydraulic Flow Modeling

Production Engineering and

Corrosion and Erosion Modeling

Thermodynamic Modeling

Viking’s Modeling and Technology Team develops fit-for-purpose software solutions and customized testing to solve very complex engineering problems, including failure investigations in legal cases.

Viking’s Team has developed in-house software models for different clients in the following areas:

Corrosion Modeling for Specific Field Applications

Materials Selection based on Erosion, Corrosion, and Sulfide Stress Cracking Performance.

Corrosion / Erosion Tool for Production Optimization

Fracture Mechanics Calculations.

Our Modeling & Technology Lab Services

Finite Element Analysis (FEA)

Thermo-hydraulic Modeling

Corrosion and Erosion Modeling

Fracture Mechanics Modeling

Fatigue and Stress Analysis

Thermodynamic Modeling

Fit-for-Purpose Software Design

Equipment Sneak Peeks

Dive into our YouTube channel for exclusive previews of the latest lab equipment we use for failure analyses. From surface grinders to Charpy impact testers, we take you behind the scenes to witness our high-tech lab equipment.

Consult Our Specialist

Related Resources