Meet GATE Prho™

The Engine We Use To Configure Custom Tools for Our Clients

At Viking, our Engineering team leverages our proprietary in-house fluid flow and thermo-hydraulics engine against your challenges. By customizing our tools, we help you make better, faster decisions the first time. Take a look at our process and some of the tools we have specifically configured to meet our clients’ needs.

By utilizing our in-house developed GATE Prho™ system, we can support our clients from initial start-up to well optimization and life extension. The GATE Prho™ suite of tools help our clients make better, faster decisions the first time with less down time for onshore verification.

Need a Custom Digital Tool?

Through recognizing our clients’ needs, our engineering expertise, and our proprietary in-house GATE Prho™ software engine, we provide customizable, cost-effective, easy-to use software tools to deliver better client outcomes quicker.

CUSTOMIZABLE

With a systems focus, open-ended computer code and customizable Graphical User Interface (GUI), GATE Prho™ engine can be modified to meet specific client needs and/or analyze unique production challenges.

BENCHMARKED & ACCURATE

The GATE Prho™ engine employs a rigorous multiphase flow, heat transfer, pressure-volume-temperature (PVT) models, benchmarked with field data and experimental results.

EASY TO USE & FAST RESULTS

Our solutions are designed for non-experts. Get the results when you need them, backed by our engineering experience.

Our Process

The Engineering team works with our clients to integrate the software into their systems and workflows to get real-time results and allow for real-time decision making. We can build a unique user interface or work with your current existing user-interface platform.

We can create custom digital tools such as:

Custom Process Dashboard Development

Custom Corrosion-Erosion Management Tools

As-needed Custom Tools

Flowline Virtual Metering Tool

Viking developed a flowline virtual metering system that, in real time, allows the operator to:

Create PT Profiles: Determine the current pressure and temperature profiles through water-oil-gas multiphase hydrodynamic calculation.

Understand Flow Distribution: Calculate the production flow split / distribution through XOVs and evaluate the potential instability. This helps the operator to make decisions on topside backpressure as well as opening/closing the XOV valves.

Create PT Profiles: determine the current pressure and temperature profiles through water-oil-gas multiphase hydrodynamic calculation.

Perform a High-level Wax Risk Assessment: evaluate the temperature profile along the flowlines to determine where paraffin may potentially deposit.

Understand Flow Distribution: Calculate the production flow split / distribution through XOVs and evaluate the potential instability.

Confirm Water Sweep Velocity: Analyze the oil in-situ velocity along the flowlines and determine where it is not enough to sweep the water and causing water accumulation.

Determine Water Content: Calculate how much water is in the system and determine how much inhibitors required to inhibit the water from forming hydrates during shut in condition and subsequent restart.

Calculate Cool-down Time: Through transient cooldown simulation, calculate the duration until where fluid pressure and temperature are favorable for hydrate

Prior to delivering the surveillance tool, GATE conducted an extensive benchmarking study between the tool and the available field data to ensure it is representative of the actual field conditions.

Flowline Assurance Surveillance Tool

Viking developed an integrable comprehensive flow assurance surveillance tool that, with one simulation run, allows the operator to:

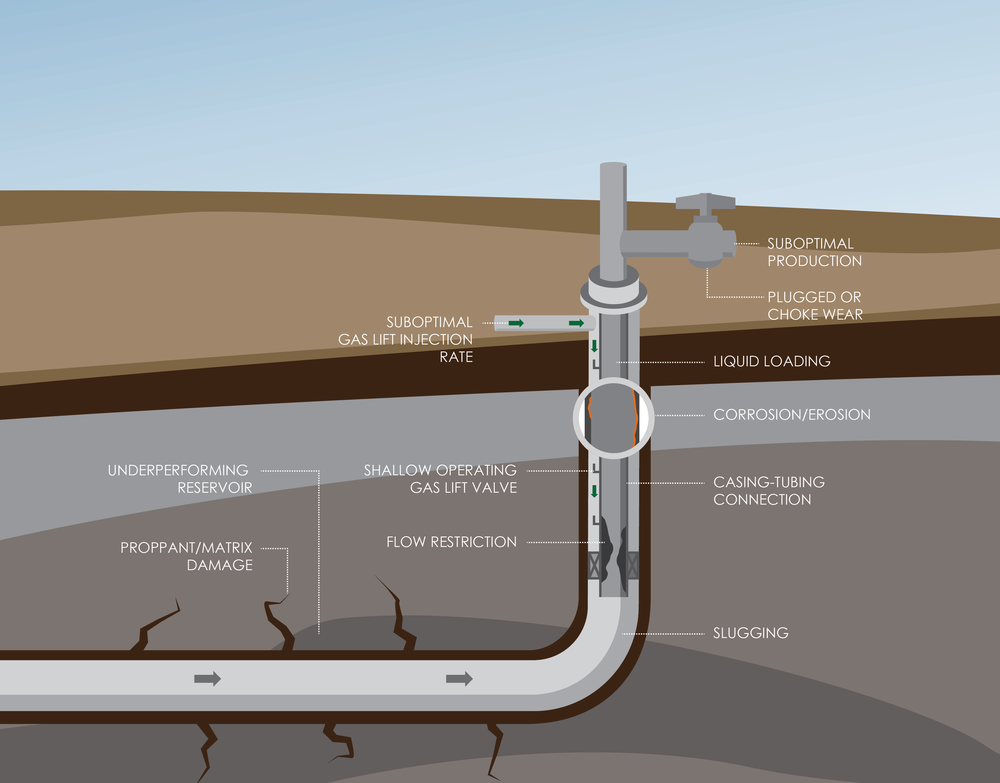

Gas Lift Optimization & Well Surveillance Tool

Viking developed a comprehensive well operations tool utilizing Viking’s proprietary simulator GATE Prho™ building blocks and Time-lapse Nodal Analysis that allows the operator to:

Perform real-time simulation through connection with SCADA system

Evaluate underperforming wells

Quantify potential production enhancement through gas lift optimization

Determine the operating gas lift valve

Evaluate liquid loading risk

Perform Rate Transient Analysis (RTA)

Generate the gas lift performance curve

List the potential well issues and provide the recommendations

Detect potential flow restriction

Detect leaks for integrity

Prior to delivering the surveillance tool, Viking conducted an extensive benchmarking study between the tool and the available field data to ensure it is representative of the actual field conditions.

SCSSV Leak Rate Calculation Tool

The SCSSV Leak Rate Calculation tool uses the GATE Prho™ engine to simulate the commonly used SCSSV leak test protocol. The engine allows the tool to account for the effects of liquid-gas interface existence in the wellbore, wellbore cool-down, wellbore venting, and suspected leakage in the USV during the SCSSV test. This improves the traditional SCSSV leak rate calculation and potentially avoids the false positive of leaked tests.

Shale Gas Well Material Assessment Tool

The Shale Gas Well Material Assessment Tool was developed to provide a preliminary guidance for tubing and tree metallurgy selection based on literature review, GATE Prho™ building blocks, and the past project experiences of GATE and Viking Engineering.

The material evaluation is performed by analyzing the Carbon Dioxide (CO2) corrosion tendency, Sulfide Stress Cracking (SSC) and Chloride Stress Corrosion Cracking risk of the materials as well as the completion/packer fluid compatibility. A cost analysis may also be carried out to determine the most economically viable design.

30-DAY FREE TRIAL

Try out our pre-built subsea modeling tool powered by GATE Prho™. This tool allows you to try the core GATE Prho™ functions free, for 30 days.

Consult Our Specialist

Related Resources