Hydrate Remediation

GATE Energy’s PM&E and BlueFin teams provide engineering and offshore execution support in successfully remediating a hydrate blockage in a multiphase, single flowline tieback.

Location: Deepwater Gulf of Mexico

BACKGROUND

A Gulf of Mexico (GoM) operator in the process of decommissioning one of its fields requested the engineering assessment of a blockage existing in their flowline-riser. The reservoir fluid characteristics and the field’s operational history were extensively reviewed. The review indicated hydrates to be the likely cause of the blockage.

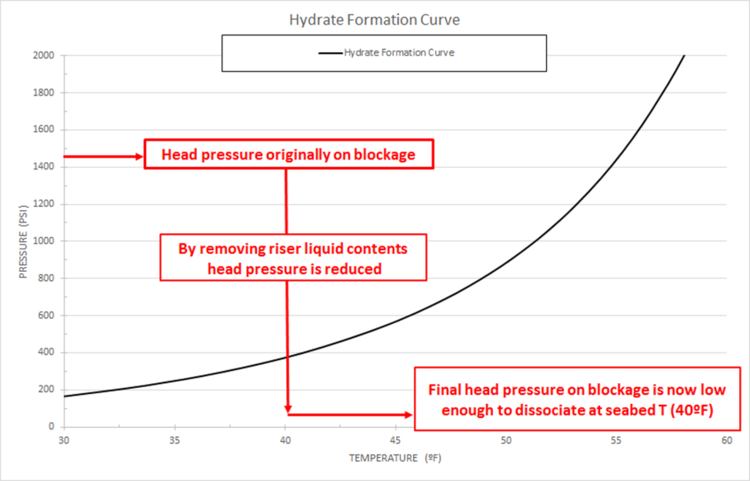

A comprehensive thermo-hydraulic model of the system was built and benchmarked against field data to determine the likely blockage location. Following numerous discussions with the operator regarding several remediation options, a remediation approach was attempted which involved lifting of the liquids in the riser to reduce the pressure head on the blockage to allow its dissociation via single-sided depressurization.

Understanding of the system’s history prior to the blockage, determining the nature of the blockage and subsequent development of the appropriate remediation solution were essential for the success of the project. The decommissioning operation demanded a cost effective solution successfully achieved by GATE’s proven systems approach.

CHALLENGE

Perform a comprehensive engineering assessment to evaluate the nature of the blockage(s) and better determine the potential location(s). Review the system architecture and develop a cost-effective remediation option with a high likelihood of success. Following blockage remediation, provide flowline flushing recommendations to mitigate the risk of forming another hydrate blockage.

SOLUTION

By better understanding the nature and location of the blockage(s), a novel remediation approach which utilized the permanent surface facilities was developed and executed. This approach consisted of running coil tubing and injecting nitrogen to help ‘lift’ the liquids in the riser, ultimately reducing the head pressure on the blockage. This significantly reduced pressure head allowed for hydrate dissociation via single sided depressurization back to the facility.

The flowline flushing plan was developed and executed with utmost care while considering the remaining flowline contents, bathymetry and required sweep velocities for this particular flowline.

TECHNICAL ACHIEVEMENTS & BENEFITS

Safely and successfully remediated the hydrate blockage which lead way for field decommissioning activities.

Avoided the mobilization of a costly Multi-service Vessel (MSV) and/or other flowline hydrate remediation skid.

Blockage remediation time was less than one week with minimal impact to the facilities’ normal operating activities.

Post blockage remediation, the flowline was flushed successfully.