Why Choose GATE Energy Commissioning?

Our Culture of Safety

GATE places a strong emphasis on Doing It Right The First Time.

GATE places a strong emphasis on Doing It Right The First Time. For us, this is not just a corporate motto, but it is a way of working that forms the foundation of our quality and health, safety, security, and environment (HSSE) operating practices and procedures. This starts with an effective on-boarding, short-service, and mentoring approach that is founded on the concepts of behavioral-based safety (BBS) and progresses to detailed vendor and site management programs with boots on the ground HSSE expertise backed by our corporate Operations Management and HSSE staff.

With over 5 million man-hours worked, GATE has a track record of never having a lost-time incident in the history of our Commissioning team or the history of our Company.

The culture of safety developed by GATE has seen the organization recognized as the 2021 recipient of the National Ocean Industries Association (NOIA) Safety in Seas Culture of Safety Award. The Culture of Safety Award honors overall immersion in and commitment to safety, which has resulted in remarkable, measurable, and sustained safety performance over a prolonged period of time and is awarded by a review board formed of BSEE, USCG, and industry health and safety experts.

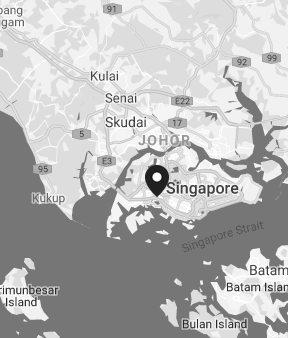

International Offices & Manpower

Tried & True Processes & Approach

GATE places a strong emphasis on Doing It Right The First Time.

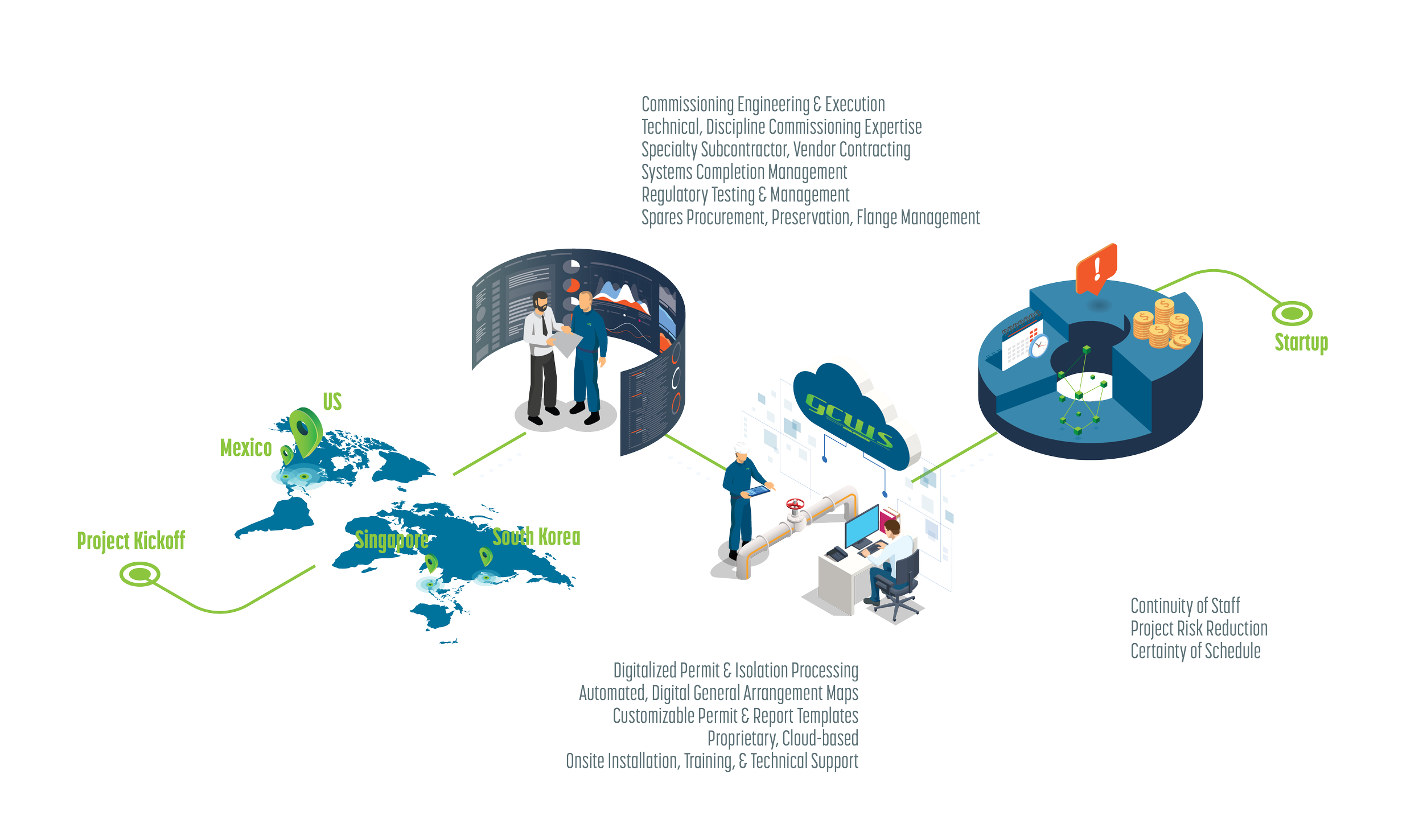

Our Services Include:

Commissioning Engineering & Execution

Technical, Discipline Commissioning Expertise

Specialty Subcontractor, Vendor Contracting

Systems Completion Management

Regulatory Testing & Management

Spares Procurement, Preservation, Flange Management

What Our Clients Are Saying…

Fully Digital Process Execution with GCWS™

GCWS™ is tailored & developed specifically for Commissioning Projects

Digitalized Permit & Isolation Processing

Automated, Digital General Arrangement Maps

Customizable Permit & Report Templates

Proprietary, Cloud-based

Onsite Installation, Training, & Technical Support

The GATE Control of Work System (GCWS™) is a proprietary, cloud-based permit to work (PTW) solution designed to fulfill most oil and gas projects, yet easily adaptable for other energy construction and commissioning projects. While other systems are typically designed for the normal operations phase of a project, GATE found that these systems aren’t always suitable to construction and commissioning needs.

GCWS™ fully digitalizes the processes, procedures and deliverables needed during construction and commissioning into a customizable software package. GCWS™ includes Permit to Work (PTW), Simultaneous Operations (SIMOPS), and Lock-Out/Tag-Out (LOTO), Risk Assessment management systems for deployment onto projects where required. These tools are key to helping us achieve the “Do It Right The First Time” goal safely.

Digital Flange Management Tool

GATE also utilizes a digital flange management tool with the following attributes:

Piping and Bolting Specs are uploaded to the software

Torqueing and bolting requirements are pre-populated in ITRs

The torqueing ITRs are exported to Systems Completion Database

Constraints, Leak Registration, and Joint Breaks are recorded on tablets in the field

Joints are identified by a QR code in the field

The VM Joint Integrity Module includes a 3D model where joint status is visually indicated by color code

”Paperless” Commissioning

GATE can execute “paperless” systems completion/commissioning of an entire project (i.e. complete digitalization) by utilizing Omega PIMs CMS. The SCDB is cloud based (with local server if necessary, backed up to the cloud) and can be accessed from any mobile device (e.g. phone or tablet).

The mobile application provides a tool where the complete inspection and testing process remains digital, allowing the construction inspector and commissioning technician to carry out work on-site and synchronize back into the main database. This real time data promotes a very economical approach to Systems Completion while providing immediate feedback to management/supervisory roles during execution.

Inspection test records (ITRs) are digitally available and completed inspections are done on-site.

Offline mode allows ITRs, preservation check sheets, procedures and punch list items to be completed digitally without requiring a wifi connection.

Punch list items may be created on-site and photographs attached (including photo mark-up tool to annotate or highlight the issue).

Task assignments are traceable per status and per user / inspector allowing workload distribution and notification.

Team members are notified on-screen and via e-mail regarding all status changes on assignments and commissioning workflow.

End-users / Inspectors will be notified via e-mail when ITR Tasks status changes occur (ITR assignments, ITR completion, rejects, etc.).

All actions in the mobile application are GPS stamped for reference.

Turnover and Completion Packages (TCP) are automatically compiled and exported in PDF Format.

No need for physical copies in binders.

Digital Leak Test Packages allows for tracking completion, leaks, flange management and witness joints.

Benefits

Task assignations to track inspections and other on-site workload statuses.

Paperless documentation / reports directly delivered to the end-user.

Real time status input into planning and reporting tools.

Affiliate Services Lead to Cost Savings

Over the last several years, GATE has made a number of acquisitions to build a cadre of affiliate companies that augment the core commissioning and engineering skills of the legacy business. Amongst these, the acquisitions of BlueFin and Mid-South Rental and Completions have provided access to services that are often subcontracted to GATE during our commissioning projects. This most commonly includes flushing, filtration, bolting, torquing, hydrotesting, and leak testing.

When GATE is able to combine such services with our commissioning scope, there is typically substantial scope for cost savings on the subcontracted items, continuity of staff, increased control of risk, and certainty of schedule. In the first instance, GATE already supports the quality and HSSE management of our affiliates from the corporate level, so there is greater alignment in work processes and procedures. This reduces the time is taken to get a vendor up to speed, whilst also eliminating the one-off quality and HSSE vetting that must be undertaken with unfamiliar contractors.

This also provides a means for GATE and our affiliates to jointly develop best practice solutions for the needs of a particular project without contractual or intellectual property concerns that can typically complicate such matters.

Furthermore, it is a philosophy at GATE that we do not double-dip such projects so that GATE does not charge a mark-up on the subcontracted services. This typically saves 10 to 15% over standard contracting arrangements and is made possible by the use of an integrated corporate accounting and invoicing system.

In cases where service providers are selected by the Client, our corporate technical depth enables subject matter review of work practices and delivery procedures to ensure that our Clients are receiving appropriate levels of service that are delivered in a way that is safe, efficient, and in alignment with the overall project objectives.

BlueFin Pre-Commissioning Services

Advantages

Continuity of Staff

Project Risk Reduction

Certainty of Schedule

10 to 15% Savings Over Standard Contracting Arrangements

Related Project Successes

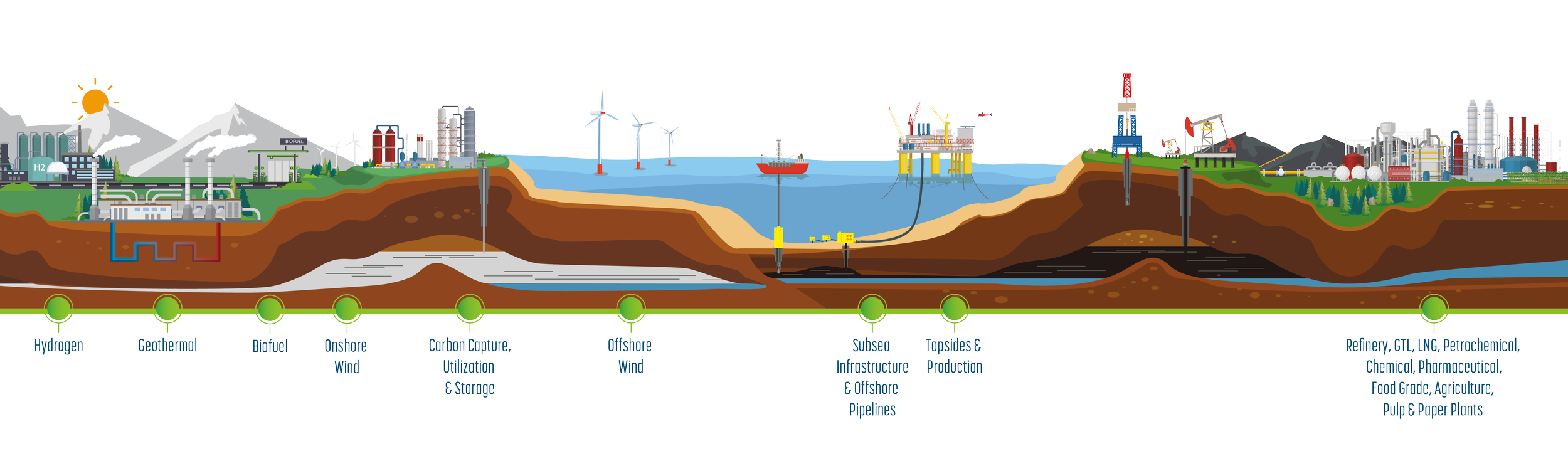

Industries We Serve

Click below to read more about our services and software: