What We Do

Services, Products, Proprietary Equipment & Training

Integrated Fracturing & Stimulation

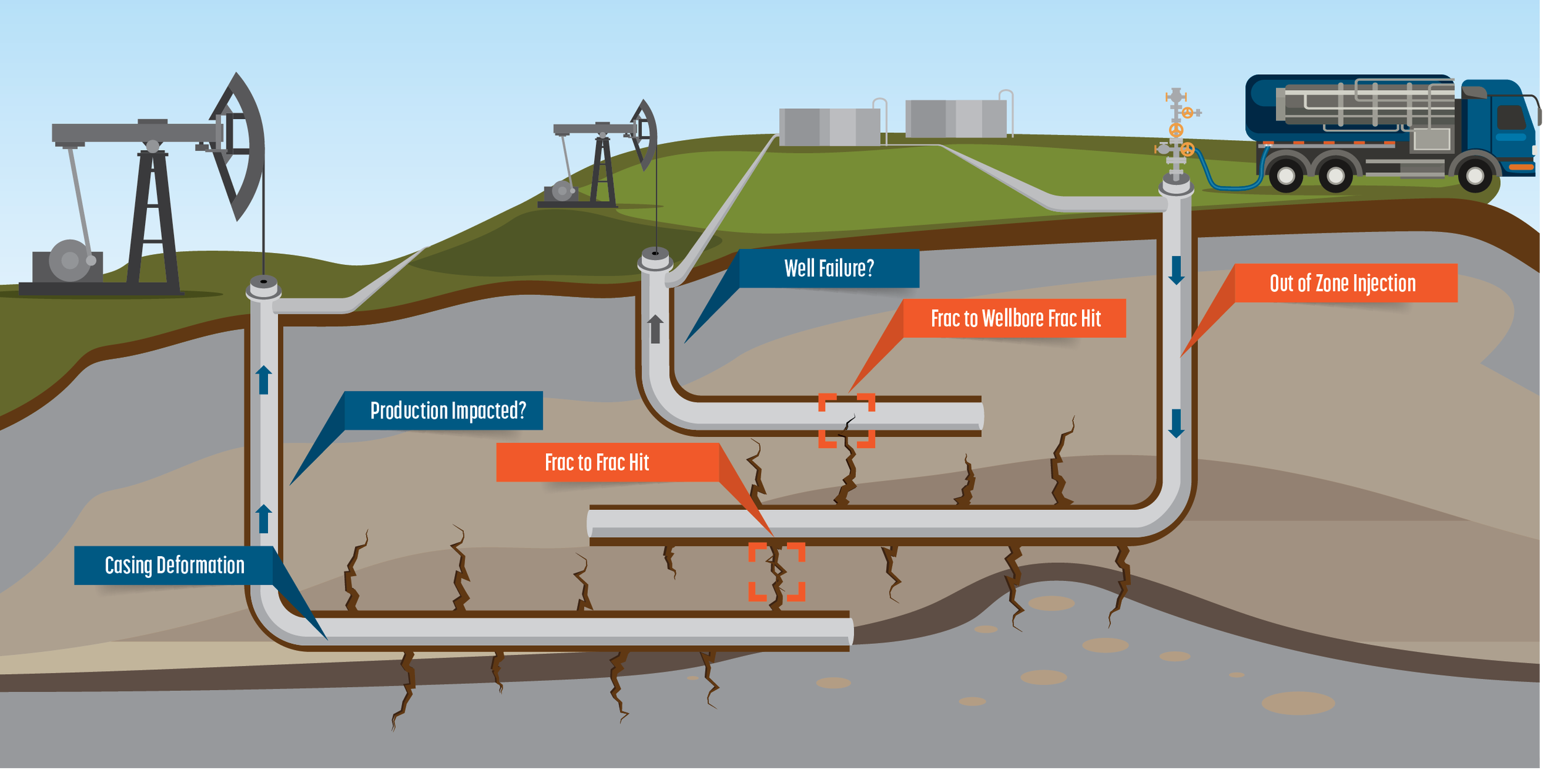

Viking has the expertise to help operators better understand past well failures and frac performance by working together to develop improved frac designs and execution.

▸ Marine & Dive Risk Management Services

The GATE Integrated Risk Management Team aims to provide solutions that target the challenges associated with offshore and marine project delivery. This includes Station Keeping ,Vessel Integrity, Marine SIMOP's and incident prevention.

▸ Operations Readiness

Preparing for operation of a major oil and gas facility is a daunting task. Viking provides standard operating procedure (SOPs) generation, maintenance planning (CMMS, Spares), FMEA and RCA studies and Control System Tuning and HMI Screen Development.

Casing & Tubular Design

Well Planning & Configuration, Tubular Design, Evaluation of Connections, WELLCAT/StressCheck/TDAS, Casing & Tubular Design Training Courses, Mill Qualification & Surveillance

Completions Operations

Viking Engineering provides onsite support for all fracturing and stimulation operations. The onsite Viking team ensures that operations are executed as it was designed and planned while making sure to achieve the project objectives. This gives our clients peace of mind throughout the process.

▸ Flow Assurance

At Viking, we take flow assurance engineering and modeling to operations. By using a systems engineering approach, Viking addresses the challenges from modeling to development of operational strategies to optimize flow assurance engineering in the production system. Flow assurance modeling is a key aspect of engineering design work, especially in deepwater oil and gas developments.

▸ Asset Integrity Services

Viking’s Materials and Corrosion Team is involved with detailed material selection and qualification support with the goal of ensuring the selection of fit for service materials and their appropriate manufacture and fabrication.

Failure Analysis & Failure Investigation

Failure analysis is a critical process in determining the physical root causes of problems. The process is complex, draws upon many different technical disciplines, and uses a variety of observation, inspection, and laboratory techniques

Metallurgical Laboratory Testing Services

Mechanical Testing, Tensile Testing, Harness Testing, Materials Chemical Analysis, Metallographic Evaluations, Fracture surface Evaluations, Microstructural Characterization, and Customized Testing

Frac Field Planning & QA/QC

Viking Engineering provides operators with a holistic and multidisciplinary approach to hydraulic fracturing and stimulation-related operations. From fracture design to execution and post-treatment analysis, Viking’s approach offers the operator technically supported decisions when conducting fracturing and stimulation operations.

Frac & Re-Frac Modeling & Design

Viking Engineering provides operators with a holistic and multidisciplinary approach to hydraulic fracturing and stimulation-related operations. From fracture design to execution and post-treatment analysis, Viking’s approach offers the operator technically supported decisions when conducting fracturing and stimulation operations.

▸ Well Construction & Design

Provides fit-for-service evaluations, testing and analysis for evaluating complex downhole failures, pipeline failure investigations and forensic services for midstream and downstream clients and also provides services to the renewable energy sector.

Integrated Marine Risk Management

The planning associated with the operation of Marine Systems should be based on managing exposure to the consequences of mal-operation, in addition to standard marine risk management objectives.

Rig Readiness

Our world-class DP experts will ensure that your asset is operationally ready to return to drilling.

Well Decommissioning

Planning for the disposal of equipment, sealing of the well safely, and recycle and reuse purposes must be performed within the regulation authority.

Topsides & Substructure Decommissioning

Topsides and substructure decommissioning capabilities.

▸ Specialty Engineering Services

In contrast to other consulting and engineering firms, GATE's philosophy is based on taking an operators prospective to a problem and not limiting ourselves to a specific discipline.

▸ Geothermal Engineering Services

Surface operational temperatures >302°F (150°C) makes well design, materials and equipment selection critical for Geothermal wells. Viking Engineering’s knowledge and expertise helps to deliver your required solutions.

Downhole Material Selection

Viking Engineering has performed many materials selection projects to help operating companies produce oil and gas safely and within budget.

A-Annulus Operating Envelope (AOE)™

The Viking team merges the mechanical and dynamic thermal-hydraulic aspects to bring a true systems approach to annulus pressure management.

- Annulus Pressure Management 1

- Asset Integrity 5

- Blockage Remediation 6

- BlueFin 38

- CAPEX 38

- Casing & Tubular Design 1

- Chemical Skid 1

- Chemical Systems 3

- Commissioning 7

- Commissioning & Startup 5

- Company Page 3

- Completion Field Services 10

- Completions & Downhole Equipment 2

- Corrosion Control 2

- Decarbonization 20

- Decommissioning 7

- Design Services 9

- Downstream 17

- Drilling 14

- Engineering 61

- Failure Analysis 4

- Filtration & Flushing 7

- Flow Assurance 9

- Fracturing & Stimulation 4

- GATE Energy 12

- GATE Prho 5

- Geothermal 10

- IM Program 5

- Industrial Field Services 8

- Instrumentation Commissioning 2

- Integrity Management 10

- Lab Services 4

- Marine 4

- Materials & Corrosion 17

- Mechanical Commissioning 2

- Midstream 25

- New Energy 22

- OPEX 56

- Oil & Gas 37

- Onshore Pipeline 28

- Onshore Production 44

- Operational Maintenance 11

- Operations 13

- Operations Readiness 5

- Optimization & Troubleshooting 7

- Other 4

- PHA 1

- PME 3

- Pipeline Cleaning 7

- Pipeline Commissioning 1