Prho™: Gas Lift Optimization and Well Surveillance Tool

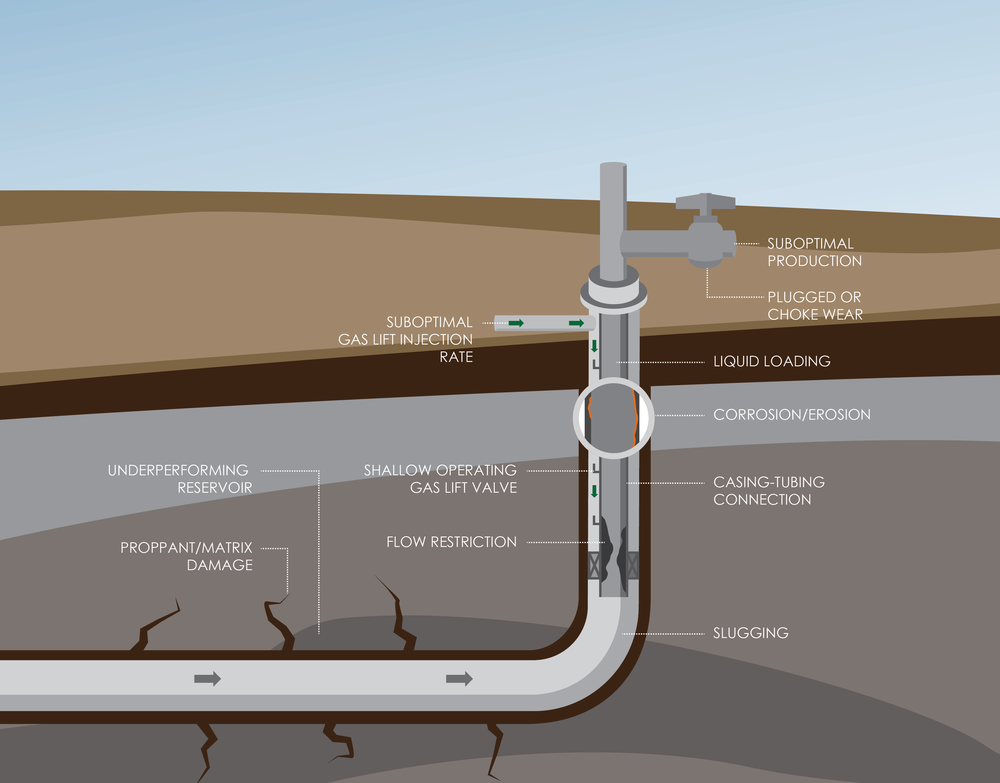

GATE developed a comprehensive well operations tool utilizing GATE’s proprietary simulator GATE Prho™ building blocks and Time-lapse Nodal Analysis that allows the operator to:

Perform real-time simulation through connection with SCADA system

Evaluate underperforming wells

Quantify potential production enhancement through gas lift optimization

Determine the operating gas lift valve

Evaluate liquid loading risk

Perform Rate Transient Analysis (RTA)

Generate the gas lift performance curve

List the potential well issues and provide the recommendations

Detect potential flow restriction

Detect leaks for integrity

Prior to delivering the surveillance tool, GATE conducted an extensive benchmarking study between the tool and the available field data to ensure it is representative of the actual field conditions.

Viking has the expertise to help operators better understand past well failures and frac performance by working together to develop improved frac designs and execution.

We offer various well services and products centered around well completions and filtration of downhole control lines and chemical lines for both onshore and offshore wells.

Well Planning & Configuration, Tubular Design, Evaluation of Connections, WELLCAT/StressCheck/TDAS, Casing & Tubular Design Training Courses, Mill Qualification & Surveillance

At Viking, we take flow assurance engineering and modeling to operations. By using a systems engineering approach, Viking addresses the challenges from modeling to development of operational strategies to optimize flow assurance engineering in the production system. Flow assurance modeling is a key aspect of engineering design work, especially in deepwater oil and gas developments.

Provides fit-for-service evaluations, testing and analysis for evaluating complex downhole failures, pipeline failure investigations and forensic services for midstream and downstream clients and also provides services to the renewable energy sector.

BlueFin offers a variety of downhole gauges that digitize pressure and temperature data downhole and then transmit to the surface using a high speed, digital telemetry link.

Capillary Injection Systems are designed for rigless operations and allow operators to inject chemicals and well monitoring at precise wellbore depths. With BlueFin’s capillary units, operators can deploy and retrieve capillary systems, thus increasing efficiency and reducing operating expenses.

BlueFin's Spooling Servies provides the mechanical solution between surface systems and downhole production enhancment and protection.

BlueFin personnel are trained in particulate counting standards such as NAS 1638, ISO 4406 and SAE 4059 rev. D and E.

MLS Trailer Units are assembled and loaded to be completely self sufficient

Multiple stage pneumatic pressure units

As part of our family of well completion products, BlueFin presents our spooling units. Designed to be compact, easy to use, safe and durable, BlueFin's spooling units provide the reliable performance you expect and need.

Safety spool baskets are designed with regard to protecting employees from injury and assets from being damaged during the loading and unloading operations of Control Line, TEC and Coiled Tubing Spools.

We offer a variety of multi-line system sheaves and spreader bars for use with control line products.

Planning for the disposal of equipment, sealing of the well safely, and recycle and reuse purposes must be performed within the regulation authority.

Topsides and substructure decommissioning capabilities.

Surface operational temperatures >302°F (150°C) makes well design, materials and equipment selection critical for Geothermal wells. Viking Engineering’s knowledge and expertise helps to deliver your required solutions.

Complete Lifecycle Stress Analysis, Completion Design, Downhole Equipment Evaluation

The Corrosion and Materials Team for oil and gas developments and water and gas injection systems forms one of Viking’s core oil and gas engineering services.

Viking’s is engaged in all aspects of chemical-related technology for offshore and onshore facilities. The team focuses on production chemistry solutions, chemical injection system design and chemical umbilical commissioning.

The primary focus of the Water Injection Team is to provide systems engineering solutions to waterflood design, commissioning, and system operability.